As car interiors keep improving and eco rules get tighter, floor mats aren’t just simple carpets anymore. Now they help protect your car, look better, feel more comfortable, and keep things clean and safe. Gluebar is one of the top TPE mat makers in China. We’ve got a 27,000 m² modern factory, over 300 skilled workers, and we make about 1.5 million mats every year. Our mats fit well, have raised edges, and use eco‑friendly materials.

Why Choose TPE Floor Mats?

High Performance Meets Green Standards

Car makers now face stricter eco rules, and drivers care more about air quality and sustainability. TPE (Thermoplastic Elastomer) bends and bounces like rubber but shapes like plastic. It’s non‑toxic, odor‑free, and meets RoHS and REACH standards. You can even recycle it with heat. By contrast, PVC mats often contain harsh chemicals and crack in extreme heat or cold. Fabric mats soak up water, grow mold, and are hard to clean.

Lower Cost Over Time

TPE mats cost a bit more up front, but they last 3–5 years. You don’t need to swap them out often, and cleaning is easy. Over their full life, TPE mats end up costing less than other types of mats.

Photo Breakdown: Fit, Clips & Raised Edges

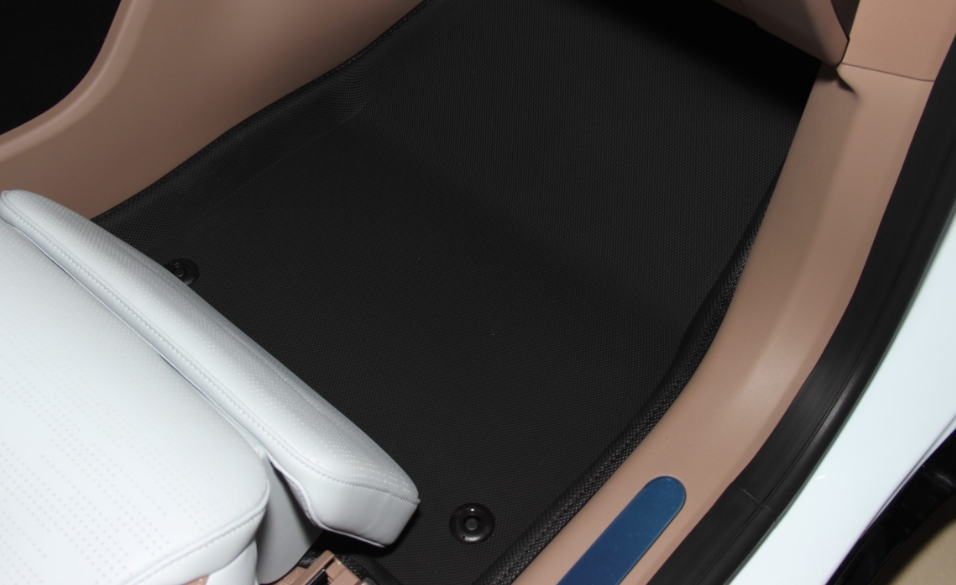

1. Raised Edge, Perfect Fit, No Gaps

The first photo shows the mat hugging the door sill and sliding rail area. It folds over the edges without seams, wrapping the whole footwell. This stops dirt and dust from sneaking under your car’s carpet.

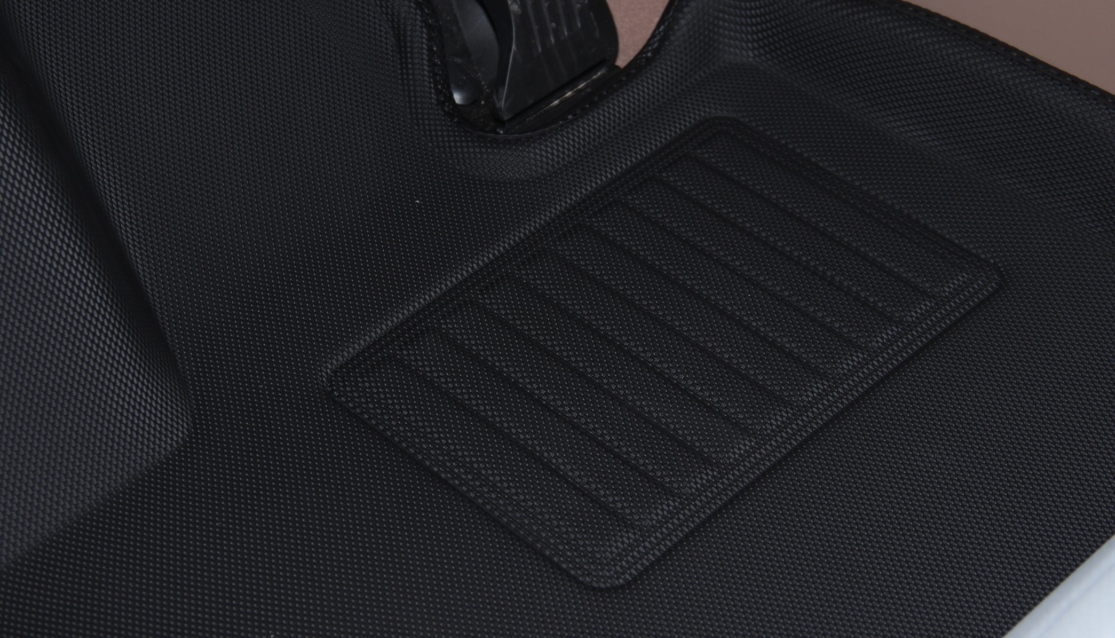

2. Clip Alignment for Anti‑Slip

The second photo shows the OEM clip holes on the mat’s back and the closed‑cell grip texture. When you speed up or brake hard, the mat stays locked in place—no sliding or curling—to keep you safe.

3. Raised Edges for Water Control

The third photo zooms in on the 15–20 mm lip that forms a tray around the mat. Rain or spills stay inside. Just tip it out or wipe with a cloth. No deep scrubbing needed.

Material Comparison: TPE vs. Traditional Materials

| Material | Bounce & Elasticity | Temp Range | Eco-Friendly | Recyclable | Cost |

|---|---|---|---|---|---|

| TPE | Excellent | –30℃ to +80℃ | Non-toxic, no odor | Heat-melt recycle | Mid-high |

| PVC/Rubber | Fair to Medium | –10℃ to +60℃ | Contains plasticizer | Not recyclable | Lower |

| Nylon/Fabric | Medium | –20℃ to +70℃ | Textile residues | High-energy recycle | Higher |

Bounce & Recovery: TPE’s closed‑cell foam snaps back quickly after you step on it and won’t sag. PVC mats can harden and crack over time.

Extreme Weather: TPE works from –30℃ to +80℃, so it’s fine in both freezing winters and scorching summers. PVC and fabric mats can get brittle in the cold and warp in the heat.

Green & Recyclable: TPE has no harmful fumes and you can recycle it by melting it down. PVC or nylon mats often have plasticizers or fabric residues, making them hard to recycle.

Cost Over Time: TPE mats cost a bit more upfront but last 3–5 years and need little upkeep. Over their life, they end up being cheaper than other mats.

Precision Crafting: From Raw Material to Final Mat

1. Raw Material Prep

Drying: Heat TPE and XPE pellets at 80℃ in a vacuum for 4 hours. This keeps moisture out and prevents uneven bubbles.

Screening: Sift the dried pellets through a 60‑mesh screen to remove big chunks and dirt.

2. Formula Mixing

Ratio: Mix TPE and XPE at 75:25 (adjustable).

Additives: Stir in 1% anti‑aging agent, 0.5% UV stabilizer, and up to 3% colorant.

Blending: In a sealed mixer at low speed, mix for 5–8 minutes until everything is even.

3. Extrusion & Foaming

Machine: Use a twin‑screw extruder.

Temperature: Set zones between 180–220℃.

Speed: Run the screws at 40 rpm.

Result: The material foams inside, making a uniform closed‑cell structure at 0.5–0.8 g/cm³.

4. Rolling to Thickness

The foam sheet goes through rollers until it’s 5–8 mm thick. A cooling roller locks in the shape, with a tight tolerance of ±0.2 mm.

5. Heat‑Press Molding

We use CNC molds with accuracy up to 0.1 mm. The hot press runs at 160℃ and 8 MPa for 45 seconds. This fuses the Flock surface to the base in one piece.

6. Trimming & Cleaning

A high‑speed cutter trims the edges to within 0.2 mm. Then we use electrostatic dust removal and an air knife to clear any leftover debris.

Quality Control: Tests That Ensure Top Performance

To make sure our mats perform in any situation, Gluebar runs six tests:

1. Look & Measure

We inspect each mat for scratches or bubbles. Then we use digital calipers to check length, width, thickness, and edge height (±0.5 mm).

2. Physical Strength

We test Tensile Strength (≥ 8 MPa). We press the mat and check bounce‑back (≥ 85% in 1 minute). We run a Taber wear test (≤ 0.1 g loss per 1,000 turns).

3. Function Tests

We check the grip (friction ≥ 0.6). We pour water and watch for leaks (no leaks in 3 minutes). We do a heat‑age test at 90℃ for 72 hours (no cracks).

4. Climate Aging

We cycle mats through hot and cold, blast UV light, and spray salt fog. This ensures they hold up in any climate.

5. Safety & Compliance

We meet global eco rules. Our mats are safe to export to Europe, the Middle East, and Southeast Asia.

6. User Feedback

We regularly ask partners and customers to try our mats and share their thoughts. Their feedback drives our next round of improvements.

Maintenance & Care: Simple and Convenient

Everyday Cleaning: The closed‑cell surface stops dirt and mud from sinking in. Just rinse with a hose or wipe with a damp cloth, and it air‑dries in about 3 minutes.

Routine Care: We suggest a deep clean once a month. Check the clip holes and edges for wear, and patch small worn spots if needed.

After‑Sales Support: Gluebar offers a 3‑year warranty. If a mat fails under normal use, we’ll replace it for free. And our customer managers are online 24/7 to help.

Pick Gluebar TPE All Weather mats and get eco‑friendly, perfect fit, and raised‑edge protection. You also get lasting quality and helpful support. Whether you drive to work or off‑road, your car’s floor stays clean and you drive with peace of mind. OEMs, dealers, and end users are welcome to ask about custom orders and bulk buys. Let’s start a new era of car interior protection together!