For importers who are just entering the automotive accessories sector, car floor mats are often the most common starting point. They offer stable demand, manageable size for shipping, and broad model compatibility. Floor mats not only help businesses enter the market quickly but also serve as the first step to verifying supply chains and quality systems. However, to achieve long-term competitiveness, it’s essential to fully understand the manufacturing process.

Car Mat Manufacturing Process: From Raw Material to Finished Product

Raw Material Selection

The foundation of high-quality car floor mats lies in both materials and design. Gluebar uses eco-friendly TPE material combined with a one-piece hot-press molding process, delivering mats that are odor-free, wear-resistant, waterproof, anti-slip, and easy to clean—meeting the green product requirements of markets worldwide. Compared with traditional PVC or low-cost rubber, eco TPE mats are not only more popular among B2B importers but also provide long-term value and brand recognition for end users.

“All-weather” TPE mats are designed to handle complex conditions such as rain, snow, mud, and dust. They are waterproof, anti-slip, durable, and easy to maintain, helping reduce vehicle upkeep costs. Because of their stability and wide market appeal, these products are easier to promote at scale across international markets, making them an ideal choice for importers seeking continuous sales and sustainable growth.

By contrast, PVC and low-cost rubber mats may be cheaper, but they often suffer from unpleasant odors, poor durability, and high compliance risks in terms of environmental standards. Leather full-coverage mats emphasize luxury appearance but are difficult to clean, costly to transport, and unsuitable for mass export or global distribution.

Car Mat Manufacturing Process: Six Key Production Steps

The production of car floor mats is much like tailoring clothes—every stage requires strict quality control. For importers and wholesalers, these steps not only determine product quality but also directly impact costs, lead times, and overall market competitiveness.

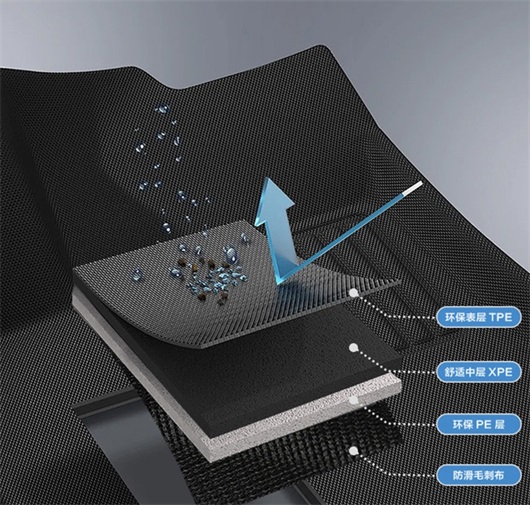

1. Composite Process

Multiple layers of eco-friendly TPE material are firmly bonded through a composite process, creating a strong structural foundation. This ensures the mats have essential features such as wear resistance, waterproofing, and slip resistance, while preventing issues like curling or deformation that are common with single-layer materials.

Value: Stable performance and consistent quality. Even in large-scale supply, product reliability remains balanced, reducing after-sales risks.

2. Cutting to Pieces

Using CAD models and mold templates for different vehicle types, materials are cut with high precision—similar to tailoring clothes for a perfect fit. This guarantees that the mats align with the contours of the car floor, avoiding oversizing or undersizing errors, which enhances both installation and user experience.

Value: Accurate fit, fewer installation errors, lower return rates, and higher end-user satisfaction.

3. Thermoforming Process

In this stage, the mats are pressed under high temperature and pressure through a one-piece thermoforming process, ensuring a perfect fit with the complex contours of the car floor. This not only enhances the three-dimensional appearance and edge coverage but also significantly improves durability and stability.

Thermoforming vs. Injection Molding

Advantages of Thermoforming:

Lower mold cost, shorter development cycle → faster response to new product demand

Better flexibility and adaptability → mats fit car floor curves more closely, balancing comfort and durability

Flexible orders → supports both large-scale and small-batch production with stable lead times

Reduced inventory pressure → enables multi-model, small-batch trial orders, helping importers minimize capital occupation and market risk

Limitations of Injection Molding:

High mold costs and upfront investment → not suitable for quick market entry

Longer development cycle → delays product launch

Lack of flexibility → difficult to support multiple models and small-batch customization, leading to higher inventory pressure

Value: Thermoforming helps importers reduce upfront investment and inventory pressure, while maintaining flexibility and delivery efficiency—ideal for both trial orders and large-scale distribution.

4. Trimming

After forming, excess edges and burrs are removed to ensure clean and neat outlines. This is not only an aesthetic process but also a mark of quality. Well-finished edges enhance competitiveness in the retail market and reduce customer complaints.

Value: Improved product appearance, fewer complaints in the end market, and higher product positioning.

5. Edge Sewing

Edge sewing is like hemming trousers—it serves both functional and decorative purposes. It prevents the edges from wearing out or curling, while giving the mats a more refined look. This process improves durability and enhances premium appearance. For high-end markets and brand distributors, it is an important detail that supports higher pricing.

Value: Longer product lifespan, enhanced premium feel, and stronger potential for premium sales in high-end markets.

6. Inspection

The final stage involves strict quality testing, covering fit, slip resistance, durability, environmental compliance, and overall appearance. Every batch is delivered with a quality inspection report, helping importers clear customs smoothly and proving product reliability and compliance in the end market.

Value: Easier customs clearance, lower compliance risks, and stronger trust and credibility in end-market sales.

Quality Control at Every Step

Meeting Environmental Standards

All our mats are made with eco-compliant materials, clearly labeled as “Meets Environmental Standards.” This simplified approach avoids overcomplicated certifications, makes it easier for importers to promote, and aligns with international market requirements for sustainable products.

Multi-Stage Quality Inspection

From raw material entry to final packaging, every stage is backed by strict quality control to ensure stability and reliability:

Composite testing – Adhesion strength between layers, preventing delamination.

Cutting accuracy checks – Ensuring precise dimensions and no visible deviations.

Thermoforming QC – Mold tests for proper fit, avoiding curling or deformation.

Trimming and edging inspection – Clean appearance with no burrs or uneven stitching.

Functional testing – Waterproof, slip-resistance, and abrasion tests simulating real-world use.

Final inspection – Full checks on packaging, appearance, and functionality before shipment.

These multi-step quality controls not only lower return rates but also help importers build strong reputations and higher repeat purchase rates in competitive markets.

Key Considerations for Importers

While the production process ensures product quality, choosing the right partner is equally important for importers. Manufacturers with certifications such as ISO9001, IATF16949, and CQC, combined with full production capabilities, not only guarantee compliance with environmental standards but also provide stronger support in customs clearance and product testing. At the same time, services like logo customization, packaging design, and multi-language labeling help importers build differentiation in the end market, enhance brand recognition, and strengthen customer trust.

International Delivery Options

In cross-border trade, delivery terms directly affect both cost and risk. Gluebar offers multiple options including EXW, FOB, and CIF, enabling importers to choose flexibly based on their experience and market needs. Whether for large buyers with their own logistics channels or newcomers to the market, there is always a suitable option to balance cost and efficiency.

Conclusion

For importers, mastering the car floor mat manufacturing process is not just about knowing technical steps—it’s about lowering costs, shortening lead times, and ensuring compliance. The choice of manufacturing method and factory partner often determines long-term competitiveness in the international market.

At Gluebar, we combine thermoforming technology, all-weather mat design, ISO9001, IATF16949, and CQC certifications, and flexible delivery options (EXW, FOB, CIF) to give importers a reliable supply chain and strong market edge.

Choosing Gluebar means not only securing stable product supply but also leveraging our proven processes and expertise to expand faster and achieve higher ROI in global markets.

Explore our OEM/ODM Car Mats Services