Now the car mat market is very competitive, and for brands looking for a factory partner, it’s harder than before.

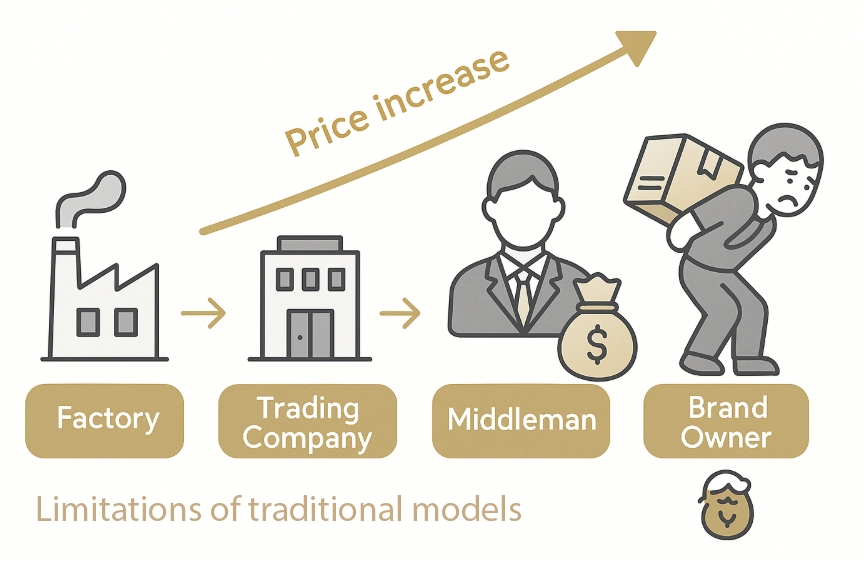

In the past, many brands bought car mats through trading companies or middlemen. This seemed easier, but the problems were clear: higher prices, lack of transparency, and unstable delivery times. Sometimes, when clients wanted customization, the middleman passed on the wrong information, and the final product was affected.

Today, more and more brands prefer to work directly with car mat factories. Doing so cuts out extra costs, gives them a clearer view of production, and ensures both quality and delivery. For brands, direct cooperation means they can compete faster and more steadily in the market.

1. Limits of the traditional model

Hidden costs of the middleman model

In the past, many brands bought car mats through trading companies or middlemen. But this brought several problems:

Layered markups → higher costs

From the factory to the middleman to the brand, each step adds a markup. In the end, the mats cost much more than buying directly from the factory.

Lack of transparency → harder quality tracking

Brands don’t really know how the mats are made, or what materials and processes are used. If there’s a quality issue, it’s hard to trace the cause.

Long communication chain → slower response and decisions

Some requests need to pass through the middleman before reaching the factory. Information gets delayed or distorted, leading to mistakes, slower lead times, and low efficiency.

Brand value is hard to extend

For car mats, branding is important. Customers don’t just buy a mat — they buy a product tied to a brand identity. But the middleman model often fails to support this:

Packaging and logo needs often ignored

Since factories don’t deal directly with brands, they can’t fully understand brand positioning. Logo customization, special packaging, and other brand-related needs are often overlooked.

Hard to keep up with fast-changing markets (like new car models)

The auto market updates quickly, with new models launching all the time. When buying through middlemen, the feedback chain is too long. The factory can’t react fast enough, and new mats can’t hit the market in time.

2. Advantages of working directly with manufacturers

More competitive costs

When brands choose to work directly with car mat factories, they cut out the middle layer. Prices become transparent, and costs are clear. You can see exactly where the money goes: materials, process, packaging — without extra markups.

Even better, long-term cooperation often comes with tiered pricing. The more you sell, the lower your average cost. This gives you an edge in market competition.

Better control of quality

Quality is the lifeline of a brand. With middlemen, you can’t see what’s happening inside the factory. With direct cooperation, you can monitor the whole process, from raw materials to finished products.

Factories are also more willing to support third-party test reports, provide certifications, and even improve processes based on your feedback. For a brand, this gives real confidence to build a stronger reputation.

Stronger customization ability

In a competitive category like car mats, brand-specific customization is key. By working directly with factories, you can achieve more:

- Custom brand logo nameplates

- Exclusive packaging design

- Multi-language labels and manuals

Factories can also respond quickly to OEM projects or adapt to new car models. When a new car hits the market, your mats can launch right away, giving you first-mover advantage.

More reliable lead times

Lead time sets the pace of your brand. By talking directly with the manufacturer, you know the production cycle and schedule clearly, cutting down on unnecessary delays.

In peak seasons or with urgent orders, factories can reserve capacity for you and handle add-on orders quickly. This means your sales plan won’t be disrupted by supply issues.

Extending brand value

The most valuable part is this: the manufacturer can act as your “invisible factory.” Without building your own plant, you still get full production and R&D support.

When customers receive high-quality, customized mats, they don’t remember the factory — they remember your brand. This trust, built up over time, becomes your brand’s real moat.

3. Case Studies and Data Support

Industry trends and market size

The global automotive interiors market is growing steadily, which means demand for products like car mats continues to rise.

According to a report from Allied Market Research, the global automotive interiors market was valued at about USD 171.2 billion in 2017 and is expected to reach USD 249.785 billion by 2025, with a CAGR of around 4.7%. This shows that as car sales increase and consumer demand upgrades, car owners are paying more attention to interior experience and details like mats.

Another Allied Market Research report notes that the global automotive interior materials market will grow from USD 55 billion in 2020 to USD 80.2 billion by 2030, with a CAGR of about 3.9%. Changes in material costs and the move toward eco-friendly trends are pushing car mat manufacturers to invest more in new sustainable materials like TPE and XPE.

In addition, research by Precedence Research predicts that the global automotive interior market will grow from USD 171.89 billion in 2024 to USD 310.44 billion by 2034, with a CAGR of about 6.13% . This shows that the market is huge and still has strong growth potential.

For brands, this data sends a clear signal: working directly with car mat manufacturers lets you capture the benefits of industry growth. It not only lowers costs but also helps you adapt quickly to changes with the support of factory R&D and capacity.

Manufacturer cooperation cases

In real cases, many brands have gained clear advantages by working directly with manufacturers. Take Gluebar as an example:

Domestic cooperation: Gluebar has built long-term partnerships with OEMs like BYD, Geely, Great Wall, and JAC, supplying mats for multiple car models. This stable OEM cooperation proves its craftsmanship and quality, while also letting brand clients launch new model mats right away.

Overseas cooperation: Gluebar exports mats to North America, Europe, Southeast Asia, and other regions, building rich international experience. With flexible MOQ, stable lead times, and solid after-sales support, Gluebar helps clients reduce inventory risks while steadily growing market share.

These cases show that direct cooperation with manufacturers is not only about reducing costs but also a long-term strategy to strengthen brand competitiveness.

Work directly with car mat manufacturers, grow steadily

For brands, working directly with car mat manufacturers = lower costs + higher efficiency + stronger brand control. Compared with relying on middlemen, this saves money while keeping product quality, customization, and delivery under control.

In today’s competitive global aftermarket, direct cooperation has become the natural choice for brands that want to grow long-term. It helps you adapt to changes faster, seize opportunities with new car models, and build a brand advantage that’s truly yours.

If you’re looking for a reliable partner, reach out to a car mat manufacturer for a tailored cooperation plan.

Contact us