Starting a business in car accessories means one thing: your suppliers matter just as much as your products. Car mats may look simple, but the right manufacturer can shape your brand’s reputation, customer loyalty, and even your bottom line. Let’s break down why picking the right partner isn’t just helpful—it’s necessary.

Why Choosing the Right Car Mats Manufacturer Matters

1. Protecting Brand Reputation

Customers never see the factory—they only see the car floor mats with your brand name on them.

If those mats don’t fit properly, give off an odor, or wear out too soon, buyers won’t point fingers at the factory. They’ll question the reliability of your brand.

Research from Status Labs shows that around 90% of consumers avoid doing business with companies that have a poor reputation.

That’s why partnering with a reliable car floor mat manufacturer is so important. Consistent quality protects your reputation and builds a direct link between your brand and trustworthiness.

2. Quality Control and Customer Satisfaction

A high-quality car floor mat supplier is not just a product provider, but a quality gatekeeper throughout the entire process:

From raw material selection and mold precision to production and packaging.

Strict testing to reduce defects and minimize returns.

Delivering mats that are durable, odor-free, and visually appealing.

When customers receive a product that meets these standards, they’re more likely to buy again and recommend your brand, strengthening long-term loyalty.

3. Long-Term Partnerships vs. Short-Term Temptations

Chasing the lowest price or the fastest lead time may look appealing, but it usually comes with hidden risks:

Frequent delivery delays.

Inconsistent product quality.

Supply chain instability caused by switching factories.

According to Deloitte, 85% of global supply chains experienced at least one disruption in the past year.

The smarter move is building a long-term partnership with a reliable car floor mat manufacturer. This means smoother communication, dependable supply, and more predictable operations—reducing hidden costs and giving your business a stronger base for sustainable growth.

Key Factors to Evaluate a Car Mats Manufacturer

Choosing the right partner isn’t just about price—it’s about making sure they can support your business as you grow. From materials to production speed, every detail matters. Learn more about Gluebar car mats manufacturing service.

Manufacturing Experience and Certifications

Experience shows up in the details. A factory that’s been making car mats for years knows how to avoid common problems—like mats that curl or don’t fit right. Certifications such as ISO or IATF16949 are also worth checking. They tell you the factory follows set standards instead of cutting corners. Gluebar is certified with ISO9001 and IATF16949 quality management systems, and also holds CQC product certification.

Material Quality: TPE, XPE, Rubber, and Eco-Friendly Options

Not all mats are made the same. TPE is durable and odor-free, XPE gives comfort, and rubber is tough but can smell. Some suppliers also offer eco-friendly blends. The best manufacturer will explain material options clearly and help you choose what fits your market.

Customization Capabilities (Logos,Packaging,OEM/ODM Services)

Your mats should carry your brand’s style, not just a generic look. A reliable factory should handle logo embossing, Packaging design. Ask if they provide OEM/ODM services—this shows they’re used to working with brand owners like you.

At Gluebar, we specialize in exactly this. With experience from 1,000+ successful OEM projects, we transform brand visions into tangible products. Let us show you how our OEM car mats service works

Production Capacity and Lead Time

A manufacturer's ability to meet deadlines and maintain consistent lead times is crucial for your business's success. Delays and capacity issues can lead to stockouts, increased costs, and dissatisfied customers.

A research indicates that higher lead time variability leads to increased inventory costs, stockouts, and delays in product deliveries, affecting overall supply chain performance, including inventory management, production scheduling, and order fulfillment.

Look at their production capacity and ask about lead times for both small and large batches. A steady supply helps you plan ahead and avoid empty shelves.

Global Export Experience and Compliance with Regulations

If you sell internationally, you’ll need a manufacturer that understands export rules, safety standards, and documentation. A factory with proven export experience can help you avoid customs delays and reduce costs. Gluebar is certified under ISO9001 and IATF16949 quality management systems, and also holds CQC product certification, ensuring compliance with international standards. We support multiple delivery terms, including EXW, FOB, and CIF, to flexibly meet the needs of different markets and clients. With a solid certification system and extensive export experience, we help customers navigate customs, regulations, and paperwork smoothly, ensuring products enter target markets efficiently and securely.

Red Flags to Avoid When Selecting a Manufacturer

Overpromising on Price or Delivery

If a manufacturer promises prices that seem too good to be true or delivery that’s unusually fast, be careful. Low prices often mean cheap materials, skipped quality checks, or rushed production. It might save money short-term, but it can cost your reputation in the long run.

Lack of Transparency in Raw Materials

A good manufacturer should clearly explain where materials come from and how they’re tested. If they dodge questions or give vague answers, that’s a warning sign. Knowing the material quality helps prevent issues like bad odor, poor durability, or safety problems.

No References or Verified Case Studies

Reliable factories are usually proud to share customer feedback or past success stories. If a manufacturer can’t provide references or examples of their work, it could mean they’re inexperienced or have had problems in the past.

Unique Insights from a China-Based B2B Car Mats Factory

Working directly with a factory in China gives you a peek behind the scenes. With a decade of experience in the car mat industry, we highlight some key considerations you might not notice when just ordering online or through a middleman—but that can make a big difference for your business.

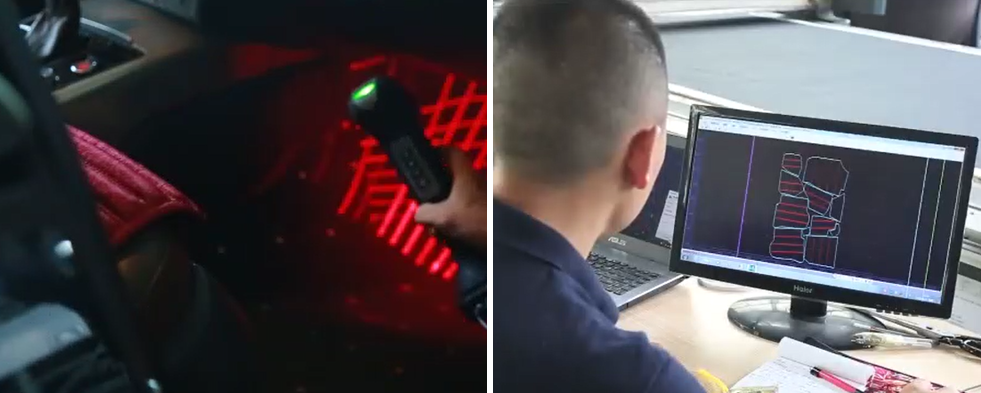

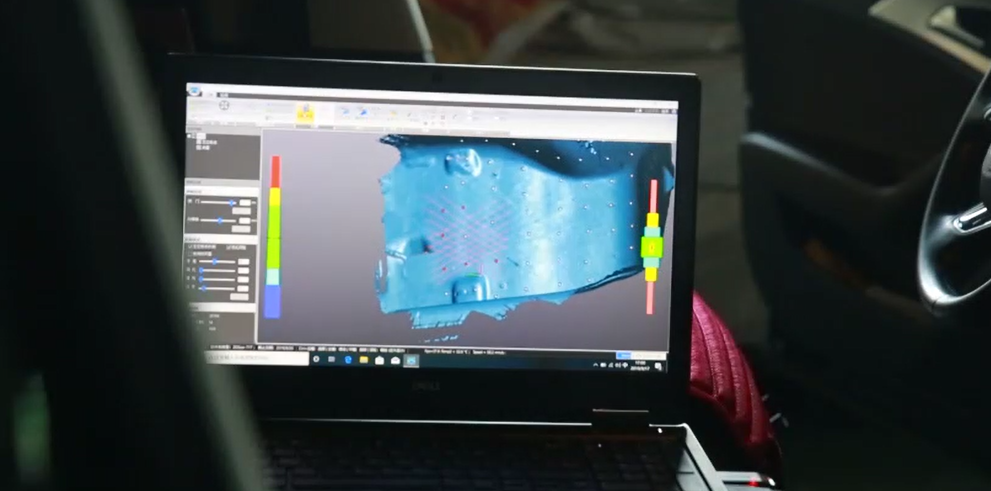

How We Ensure Consistent Mold Accuracy

Every car model has its own floor shape. Small mismatches can make a mat fit poorly. Our factory uses precise molds and regular inspections to make sure each mat fits perfectly. This reduces returns and keeps customers happy.

In-House Testing for Slip Resistance and Durability

We test mats in-house for slip resistance and durability before shipment to ensure they remain stable and long-lasting in real use.

In-House Testing for Slip Resistance and Durability

A mat that slides around or wears out too fast can ruin a customer’s experience. We test mats in-house for grip, flexibility, and long-term wear. This helps ensure every batch meets high standards before it leaves the factory.

Balancing Large Orders and Small MOQ Requests

We understand that businesses are different—some need thousands of mats at once, others just a small batch for testing. Our production process is flexible enough to handle both, without compromising quality or timing.

How to Verify a Manufacturer’s Reliability Before Signing a Contract

Before you commit, it’s smart to double-check that your factory can deliver what they promise. A few simple steps can save you headaches and make sure you’re working with a partner you can trust.

Requesting Product Samples and Test Reports

Always ask for samples first. Handling the mats yourself lets you check fit, material, and finish. Test reports from the factory, like durability or slip-resistance tests, add another layer of confidence.

Visiting the Factory or Virtual Tour Options

If possible, visit the factory in person. Seeing the production line, storage, and quality checks firsthand gives you a real sense of how they work. If travel isn’t an option, many factories offer virtual tours via video call.

Checking Customer References and Online Reviews

Ask for references from current or past clients. Honest feedback about delivery, quality, and communication tells you a lot. Also, check online reviews or business directories to spot any red flags.

Cost vs. Value – Why the Cheapest Manufacturer Is Not Always the Best Choice

It’s tempting to pick the lowest price, but cheaper isn’t always better. Cutting costs can mean lower-quality materials, rushed production, or poor packaging—all of which can hurt your business in the long run.

Hidden Costs of Poor Quality (Returns, Bad Reviews)

Cheap mats that wear out quickly or don’t fit can lead to returns and unhappy customers. Handling complaints and replacing products can end up costing more than paying a bit extra upfront for better quality.

Total Cost of Ownership vs. Unit Price

Think beyond the price per mat. Consider shipping reliability, durability, and customer satisfaction. A slightly higher price with consistent quality and on-time delivery often saves time, money, and stress over the life of your business.

Final Checklist Before Choosing Your Car Mats Manufacturer

Before you sign a contract, go through this checklist to make sure your partner is reliable and capable:

- Quality Certifications Verified – ISO, IATF16949, or other relevant certificates.

- Samples Approved and Tested – Fit, durability, odor, and slip-resistance.

- Material Transparency – Confirm TPE, XPE, rubber, or eco-friendly blends.

- Customization Options – Logos, packaging, OEM/ODM services.

- Production Capacity and Lead Time – Can handle both small and large orders.

- References and Case Studies – Customer feedback and success stories.

- Export Experience and Compliance – Regulations and paperwork for international sales.

- Quality Control Process – Testing at every production step.

- Communication and Responsiveness – Clear and prompt replies.

- Long-Term Partnership Potential – Willing to grow with your business.

Conclusion

Choosing the right car mats manufacturer can make or break your business. It’s not just about price—quality, reliability, customization, and a strong partnership all matter. Take your time to research, request samples, check references, and verify certifications. Doing this upfront saves headaches, improves customer satisfaction, and sets your business up for long-term success.

A trusted manufacturer isn’t just a supplier—they’re part of your team, helping you deliver the products your customers expect.