1. Check Manufacturing Strength: Is It a Real Factory with Certifications?

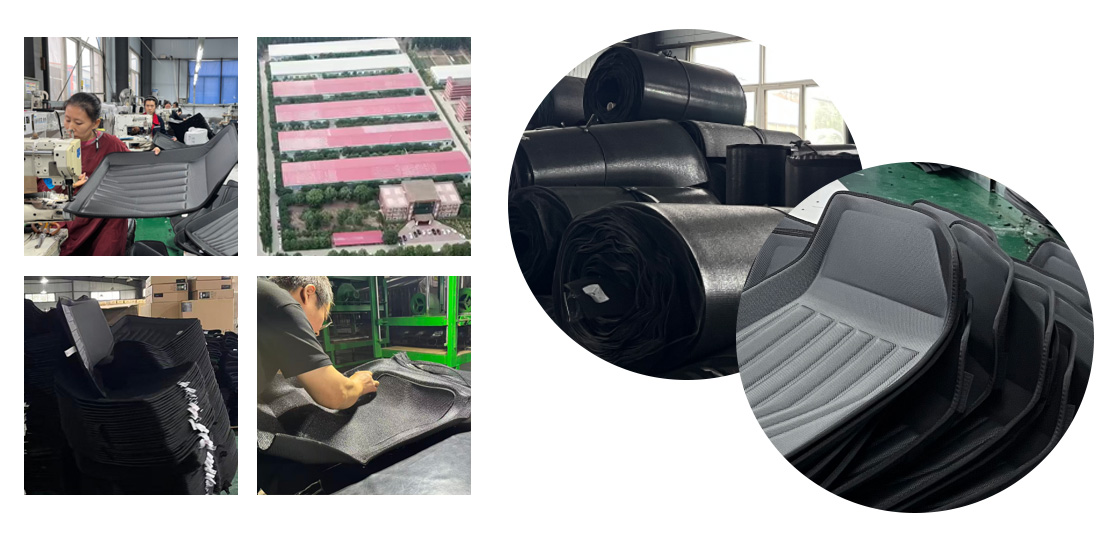

The first step in choosing a car floor mat manufacturer is to confirm they are a true production factory.

In this industry, some companies claim “factory direct,” but are actually trading intermediaries without their own equipment, technology, or quality control. Partnerships like this are hard to keep stable over the long term.

1) Do they own their factory and a complete production line?

A manufacturer with real capability usually has its own facility, equipment, and a mature production system.

For example, Gluebar runs its own plant with a full process line: material lamination → thermoforming → trimming & edging → QC & packaging, ensuring every step is controlled and traceable.

Factories like this can respond to orders faster, schedule production flexibly, and keep progress on track even in peak season.

2) Do they have international quality certifications?

Another key test of reliability is a complete certification system.

Certifications such as ISO9001, IATF16949, and CQC mean the factory has strict standards for process control, quality management, and traceability.

These factories usually pass customer audits more easily and are safer choices for exporting to Europe and North America.

3) Is capacity and lead time stable?

Beyond quality, on-time delivery matters just as much.

A factory that can produce steadily and ship on schedule gives dealers real peace of mind.

Taking Gluebar as an example:

- Monthly capacity: 100,000+ sets

- Standard lead time: 15–20 working days

- Even in peak season, production stays on pace with no shipping delays

With this level of capability, dealers don’t have to worry about “customers urging for goods while the factory falls behind.”

2. Evaluate Craftsmanship: Do They Use Quality Materials and Equipment?

A car floor mat factory with real manufacturing strength is not judged by “can they make it,”

but by how well they make it.

Materials, process, and equipment decide whether a product can stand out in the market.

1) Are the materials eco-friendly and safe?

To judge a factory’s professionalism, first look at the materials.

Today, most high-end car mats use TPE (thermoplastic elastomer).

TPE has no odor, no pollution, and is recyclable.

It is flexible and holds up under heat and cold. It is both eco-friendly and safe.

Compared with PVC or rubber, TPE mats are lighter, more wear-resistant, and free of harmful substances—better aligned with environmental rules in Europe and the U.S.

Gluebar uses TPE that meets environmental standards for all products. It protects consumer health and lifts the image of our clients’ brands.

2) Is the process advanced and stable?

Good material needs the right process to show its value.

Truly premium mats use one-piece thermoforming.

There is no splicing and no delamination.

The structure is tighter, the edges are crisper, and issues like glue failure and warping are avoided.

Gluebar’s production flow covers lamination, cutting, thermoforming, trimming, edging, and QC.

Every step is standardized to keep every set of mats at a consistent high level.

3) Do they have 3D laser scanning and precise modeling?

One core advantage of a mat is fit.

Gluebar uses 3D laser scanning and data modeling to create car-specific molds, so edges fit closely, the floor is seamless, and the mat doesn’t shift or curl. This technology supports both left-hand and right-hand drive models, fitting markets in Europe, the UK, and Southeast Asia with accuracy. For dealers, this means fewer returns and higher repeat purchases.

3. Look at Product Details: Design and Experience Are the Real Selling Points

To judge whether a car floor mat factory has real strength, don’t just look at capacity and materials. Look at detail design and user experience.

In the end, whether customers buy again often depends on how it feels to use.

1) Do they use high edges and anti-slip channel designs?

Details shape the experience.

Premium mats usually have high-edge coverage to stop mud and water from spilling over and to keep the carpet clean.

They also use anti-slip grooves and drainage channels to guide dirty water into a fixed area, making cleaning easier.

Gluebar considers real use scenarios from the design stage.

We test and refine groove depth, angle, and direction many times, so traction improves without hurting foot comfort.

This “function + experience” approach lets end users feel the difference in quality.

2) Do they use a multi-layer composite structure to boost performance?

How much tech can a single mat show? The key is its structure.

Gluebar uses a TPE + XPE + anti-slip base multi-layer composite:

TPE top layer: waterproof, anti-slip, wear-resistant.

XPE middle layer: sound-absorbing, heat-insulating, shock-damping.

Anti-slip bottom layer: stable fit, no shifting.

This structure makes the mat more durable and the drive quieter and more comfortable.

For dealers, these technical selling points are easy for end customers to understand and help support brand premium.

3) Do the packaging and instructions show brand professionalism?

A detail-oriented factory cares not only about the product, but also the unboxing experience.

Each Gluebar set includes multi-language brand cards and an installation guide.

Packaging uses eco-friendly cartons with shock-proof inserts to ensure safe transport and a clean look.

For customers, they don’t just receive a mat; they receive a complete brand experience.

This professionalism—from packaging to instructions—often becomes a key plus for both the dealer and the brand image.

4. Look at Service and Support: Is This Factory a Real Partner?

In today’s car floor mat market, dealers are no longer just “buy and resell.”

They want a manufacturer who understands partnership and win–win.

A factory with real strength doesn’t only make products—it helps dealers build a brand.

1) Brand customization and market localization

A good manufacturer understands brand value and local differences. Gluebar offers full brand customization for global dealers, including:

Custom metal insert logo plates (not embossed) to lift brand quality;

Packaging and label design tailored to your brand image and target market;

Multi-language brand cards and installation manuals—English, French, German, Italian, Portuguese, Malay, Indonesian, Hindi—

for smooth exports to North America, Europe, Oceania, Southeast Asia, Latin America, and India.

This setup matches local reading habits, builds trust faster, and helps dealers present a professional image in each market.

2) Reasonable entry threshold—can you “start small and test”?

When entering a new market, dealers worry about high stock and high risk.

Gluebar keeps things flexible—300 sets per order to start, not 300 sets per model.

You can run small trials, watch the market, then scale up step by step.

New market entrants get a steadier pace.

Established dealers can test new items without being tied down by inventory.

3) Fast response—can the factory match your pace?

Speed creates opportunity in global markets.

Gluebar can deliver samples in 5–7 days.

After confirmation, standard lead time stays at 15–20 working days, even in peak season.

We care about coordination: if you need speed, we pre-schedule and prepare materials;

if you want trial sales, we offer flexible plans.

This rhythm match is why many clients choose long-term cooperation.

4) “After-cooperation” service mindset

Partnership shouldn’t end at shipment.

Gluebar regularly collects sales feedback and end-user reviews from different markets—

which models sell best, which packaging works better—

then adjusts molds, structure, or packaging so the product keeps improving.

For us, improvement is proactive, not only after a request.

This ongoing optimization keeps Gluebar’s products at the front of the industry

and gives partners confidence to sell longer and sell steadier.

5. Look at Reputation and Transparency: Who Works With Them

1) Do they have long-term overseas clients and export records?

Real manufacturers usually have partners in many countries and regions.

Gluebar’s products are exported to North America (Canada); Europe (Germany, the UK, France, Italy); Oceania (Australia); Southeast Asia (Malaysia, Indonesia); Latin America (Brazil); and India.

Dealers in these markets choose Gluebar not only for stable product quality.

They also value our reliable lead times, responsive service, and strong cooperation.

A good factory doesn’t do “one deal and done.” It supports customers for many years.

2) Is the website transparent, and is the information real?

In the internet era, trustworthy factories don’t hide.

You should see clear proof on the website—

real workshop photos, factory videos, equipment displays, and certification documents.

There should be a factory address, contact details, and a brand story.

Gluebar’s website shows our production floor, process flow, and certifications,

including ISO9001, IATF16949, and CQC.

This lets customers see our manufacturing environment and quality system at a glance.

Openness and transparency are signs of real capability.

3) Do they welcome communication and share technical details?

A factory that truly understands manufacturing is not afraid of technical questions.

They are willing to discuss the details with you—

material differences, process principles, sampling lead time, packaging methods, and mold design.

Before cooperation, Gluebar explains our processes and sample plans in detail.

We help customers understand the standards and steps in each stage.

Our goal is not to “quote and ship.”

Our goal is to make sure you trust every set of mats—from material choice to final forming.

A Capable Factory Helps Your Business Grow Steadily

A real factory doesn’t win customers with the lowest price.

It wins trust through stable, long-term cooperation.

Gluebar knows dealers want more than a product. They want a partner who grows with them.

With steady lead times, consistent quality, clear processes, and a real factory behind it,

we help partners make their floor mat business more stable, longer-lasting, and more profitable.

Whether you are in North America, Europe, Oceania, Southeast Asia, Latin America, or India,

Gluebar will support your brand with the same standards and the same dedication—so you can reach a bigger market.