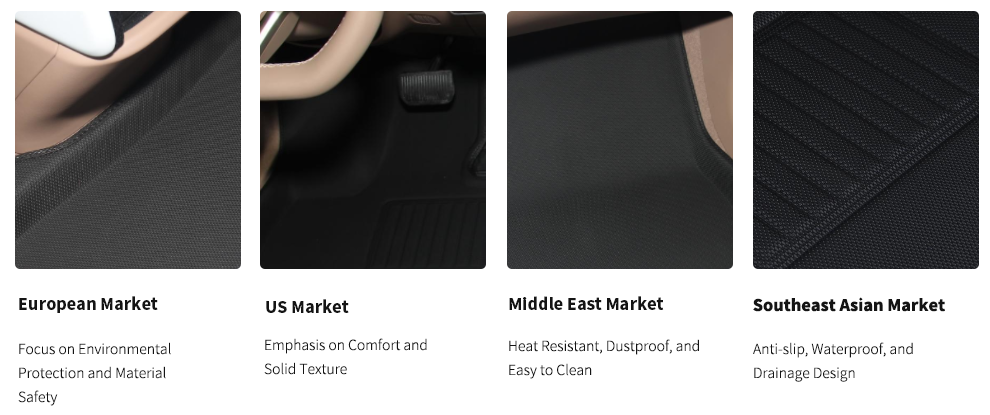

1. Why Different Markets Need Different Types of Car Floor Mats

Don't underestimate car floor mats just because they seem like a simple accessory. There are actually many factors to consider when choosing them. Users in different requirements. Significant differences in climate, road conditions, and consumer habits across regions directly influence car owners' preferences when choosing floor mats.

European Market: Focus on Environmental Protection and Material Safety

European consumers are more concerned about environmental protection and health, and have strict requirements for material safety.

They tend to choose odorless, environmentally friendly, and recyclable TPE car floor mats, which not only meet modern environmental expectations in Europe, but also reflect the brand’s social responsibility.

US Market: Emphasis on Comfort and Solid Texture

Car owners in the US market place greater emphasis on driving experience and tactile feedback. They prefer thick, flexible, and high-quality floor mats that provide stability, prevent slipping, and are easy to clean while driving.

Middle East Market: Heat Resistant, Dustproof, and Easy to Clean

The Middle East has a hot climate and frequent dust storms. Local users generally value the heat resistance, dustproof, and easy-to-clean properties of floor mats, hoping that they can maintain their shape and color without warping even in high temperatures and harsh environments.

Southeast Asian Market: Anti-slip, Waterproof, and Drainage Design

Southeast Asia is rainy and humid, with frequent road flooding.

Therefore, car owners pay more attention to the anti-slip, waterproof, and drainage groove structures of floor mats to ensure driving safety and a dry car interior.

2. Advantages and Applications of TPE Car Floor Mats

TPE is a widely adopted car floor mat material known for its environmental friendliness, safety, and durability. Compared with the commonly used rubber or PVC materials, TPE is lighter, more aesthetically pleasing, and better meets current environmental protection requirements.

Material Advantages: Environmentally Friendly, Safe, and Durable

TPE material contains no heavy metals and has no pungent odor, making it a non-toxic and environmentally friendly material.

It is highly elastic, resistant to wear and tear, and waterproof. It will not deform or harden regardless of weather conditions.

Furthermore, it is lighter than rubber, helping to reduce the weight of cars and improve fuel efficiency.

Applicable Vehicle Types: Suitable for a variety of vehicles

TPE floor mats are compatible with many vehicle types, such as sedans, SUVs, pickup trucks, and commercial vehicles.

Because of their softness, they can be precisely fitted to the floor of each vehicle using laser scanning.

Whether it's a family car or a commercial vehicle, they fit snugly and look neater.

Manufacturing Process: Hot-press Molding and Laser Bonding

TPE floor mats utilize a hot-press molding process, eliminating the need for traditional injection molds and enabling the creation of precise shapes.

This method saves production time and results in a smoother surface and a more secure edge seal.

Combined with 3D laser scanning and precise digital modeling, each set of floor mats precisely conforms to the bottom of the car, providing not only slip resistance and waterproofing but also stability under various temperatures.

3. Choosing the type of TPE car floor mats based on market conditions

Climate, road conditions, and usage habits vary across regions, influencing car owners' needs for floor mat functionality. Understanding the characteristics of each market and selecting the appropriate type of TPE floor mats allows products to better meet real-world usage scenarios and gain customer approval more easily.

Cold Regions: Freeze Protection and Slip Resistance are Key

In cold regions like Northern Europe and Canada, winter temperatures are very low, and the ground is often covered in ice and snow.

Floor mats in these environments need to be freeze-resistant and not harden, while also having a slip-resistant bottom layer to enhance driving safety.

TPE material remains soft and stable at low temperatures, making it an ideal choice for this market.

High-temperature, dry regions: Heat-resistant, dust-proof, and easy to clean

Parts of the Middle East, Australia, and Africa experience strong sunlight, high temperatures, and frequent dust storms year-round.

Car floor mats used here need to be heat-resistant, non-deforming, dust-proof, and easy to clean.

A finely textured or closed-cell surface prevents dust from settling into the surface texture, extending its lifespan.

Rainy and Humid Regions: Waterproofing and Mold Prevention are More Important

In rainy and humid regions such as Southeast Asia and the coast of South America, vehicles are often affected by rain and mud.

It is recommended to use floor mats with drainage channels and anti-slip, mold-resistant structures.

These effectively drain water, prevent odors, and keep the cabin dry and clean.

High-End Vehicle Market: Comfort and Quietness

In markets with a strong demand for premium interiors — such as Europe, the U.S., and Japan — where car owners have higher demands for interior quality.

These markets are well-suited to TPE + suede composite floor mats, which offer both a waterproof base and a soft surface.

They effectively absorb sound and reduce noise, enhancing the overall quietness and comfort of the vehicle, better meeting the expectations of high-end customers.

4.Choose TPE Car Floor Mat Styles Based on Customer Segments

Different types of customers focus on different things when buying TPE car floor mats. Understanding their traits and how they make decisions helps you offer the right products and services — making partnerships smoother and more reliable.

4S Shops and Dealers: Focus on Brand Image and Model Coverage

4S shops and dealers serve end customers, so they care most about appearance, brand identity, and complete packaging.

They prefer product lines with a strong brand feel, wide model compatibility, and refined packaging to enhance display appeal and customer trust.

Consistent metal logo badges, professional packaging design, and premium surface finishes are key elements that help dealers boost sales.

OEM / Aftermarket Shops: Want Customization and Stable Delivery

OEM and aftermarket customers care about exact fit, consistent craftsmanship, and how flexible the product is for customization.

They usually need Customer Brand Logo Service, fast sampling (3–5 days), and reliable delivery (15–20 days).

Gluebar’s TPE one-piece hot-press process and laser scanning modeling can meet these high-precision custom needs.

E-commerce Platforms and Wholesalers: Care About Cost and Inventory

E-commerce sellers and wholesalers focus more on price, delivery speed, and how easy it is to manage stock.

They prefer standardized, universal TPE floor mats that are easy to buy in bulk and ship fast.

In this kind of market, good pricing, easy-to-clean products, and low return rates are the key to long-term cooperation.

Fleet and Corporate Clients: Focus on Durability and Maintenance Cost

Fleets, taxis, and company vehicles are used a lot every day, so they need floor mats that are wear-resistant, stain-resistant, and easy to clean.

They tend to choose thicker, dirt-proof, and easy-to-replace TPE mats to extend service life and lower daily maintenance costs.

Gluebar’s high-density TPE material performs very well in this market, offering both stability and cost efficiency.

5. Key Criteria for Evaluating TPE Car Floor Mats Suppliers

Choosing a reliable TPE car floor mats manufacturer doesn’t just affect product quality — it also impacts delivery speed and your brand reputation.

For dealers, OEM factories, and brand owners, doing a full supplier assessment before working together is a key step to make sure the project runs smoothly.

Quality system certification: the base of professional production

A reliable car floor mats manufacturer needs a solid quality management system.

Passing international standards like ISO9001 and IATF16949 is the first thing to check if you want to know whether their production is standard and stable.

These systems make sure every step — from raw materials to finished products — is traceable and controlled, which helps cut defects and rework.

Mold and delivery capability: speed and accuracy together

The fit of TPE floor mats depends on high-precision molds.

A good factory should be able to design and develop molds on its own, make samples in 3–5 days, and finish bulk delivery in 15–20 days.

Only suppliers that can respond fast can stay competitive when car models and the market move quickly.

OEM customization: support for brand-based operations

A good supplier should offer full OEM services, including:

- Logo customization (Customer Brand Logo Service)

- Brand packaging design (with multi-language labels and carton style)

- Custom instruction cards and installation manuals

- Unified visual style and sample confirmation

These services help customers build their own brand image and make the product look more professional and recognizable in the market.

Order flexibility: support for different cooperation sizes

In the global market, order sizes can be very different.

A professional car floor mat manufacturer should offer flexible MOQs — for example, 300 sets per PO, instead of setting a minimum for each single car model.

This flexibility lets customers mix different models in one order and helps reduce inventory pressure.

Process stability: one-piece hot-pressing has the edge

Compared with traditional injection molding, one-piece hot-pressing keeps the strength while improving the look, the fit, and the edge sealing.

This process also lowers energy use, shortens the production cycle, and keeps the surface flat and non-slip.

Factories with a mature hot-pressing line can usually offer more consistent product quality.

Export experience and market feedback: proof of real capability

When you evaluate a supplier, you should also look at their export history and reputation.

Check whether they have long-term deals with brands or distributors in different countries, and whether they have a good system for getting feedback and improving.

A manufacturer with years of export experience, who knows overseas rules and packaging standards, can give more stable support during delivery.

The right floor mats lead to better market feedback and customer satisfaction

Choosing floor mats is never just picking a product — it’s about choosing your brand position.

For different countries and regions, the right mats mean higher customer satisfaction, fewer after-sales issues, and stronger brand impact. Whether your market is in Europe and the U.S., Southeast Asia, or the Middle East, Gluebar can customize TPE floor mats based on climate, buying habits, and vehicle structure.

We believe only by truly understanding the market, caring about details, and keeping good quality can you earn long-term trust from global customers. Let every market have its own perfect TPE car floor mat solution.