In the global auto industry’s push toward green transformation, environmental standards have become a must for entering international markets. The EU REACH regulation, California’s VOC limits, and stricter rules across Asia all set tough requirements for interior car materials. For dealers and buyers, if car mats don’t meet these rules, it could mean blocked market access, product returns, fines, or even damage to brand reputation.

Gluebar as a professional modern car mat manufacturer, has long focused on eco-friendly TPE material. With 3D scanning, precise molds, and sustainable production, we make sure products meet REACH, ISO9001, IATF16949, and other international standards. Our goal is to give global dealers and buyers stable, compliant, and competitive car mat solutions, helping partners stay ahead in the shift toward green supply chains.

Why Eco-Friendly Materials Matter in Modern Car Mats

The global shift toward green cars

In recent years, the auto industry has been going through a deep green transformation, from Europe to Asia. The EU REACH regulation puts strict limits on harmful chemicals. California’s VOC rules set standards for in-car air quality. Countries like China and Japan are also raising the bar for eco-friendly car materials. For a global brand like Hyundai, its supply chain must meet these rules. Otherwise, the products may face customs barriers or even sales bans.

For dealers and buyers, choosing eco-friendly Hyundai car mats is no longer optional. It has become a must for entering international markets. If the mats fail to meet eco standards, they may be returned, cause extra compliance costs, and even hurt long-term business partnerships. That’s why eco-friendly mats are key to entering markets in Europe, the U.S., and Asia smoothly.

New Demands From Consumers: Odor-Free, Sustainable, Safe

Beyond regulations, changing consumer needs are also driving the rise of eco-friendly car mats. When buying a car or replacing mats, drivers now care more about health and the environment:

- Air quality inside the car: Traditional PVC or low-quality rubber mats often give off strong odors and may release harmful substances, which affect the cabin environment.

- Sustainability: Many buyers want to know if the mats are recyclable and eco-friendly.

- Safety: Eco-friendly mats are often made with better design and craft, such as anti-slip, wear resistance, and leak protection, which improve driving safety.

Compared with these, TPE Hyundai car mats are odor-free, recyclable, and perform better in comfort and durability. They have become a trusted “green choice” for consumers. For dealers, such products are easier to win customer approval and repeat purchases.

Hyundai Owners Care About Eco-Friendly Interior Solutions

Hyundai drivers are spread across markets in Europe, the U.S., and Asia. Many of them pay close attention to the environmental impact of their cars. They not only care about fuel use and emissions but also the eco performance of interior materials.

Eco-friendly Hyundai car mats help cut down odors inside the cabin and prevent harmful emissions. They also show Hyundai’s commitment to greener mobility. For dealers, offering these mats matches the buying trends of car owners. It also helps build a more professional and trustworthy image in their sales channels. In the long run, this advantage makes it easier to stand out in a highly competitive market.

TPE Car Floor Mats: A Blend of Eco and Durability

Why Choose TPE?

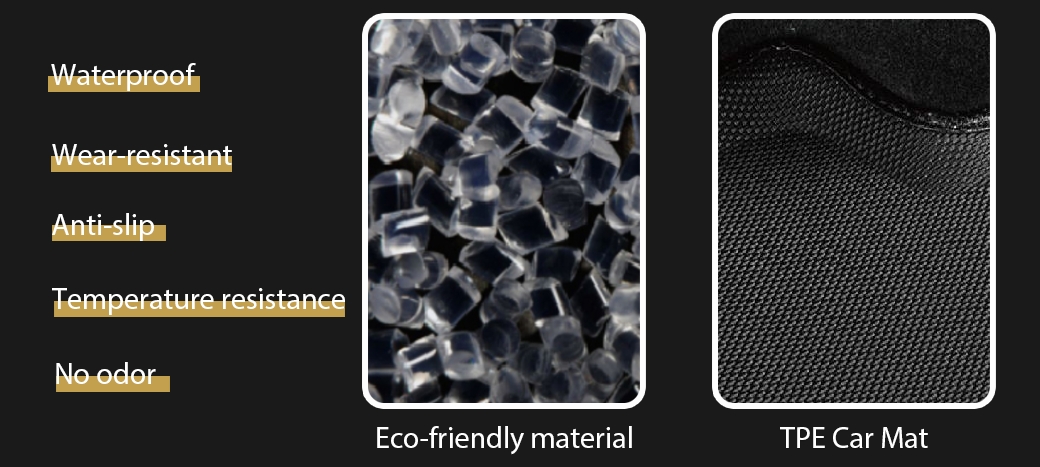

When it comes to Hyundai car mats, TPE is slowly replacing the older PVC material. The reason is simple: TPE is recyclable, has lower emissions, and meets eco standards in Europe, the U.S., and Asia. For dealers, it’s also safer because it avoids trouble with exports.

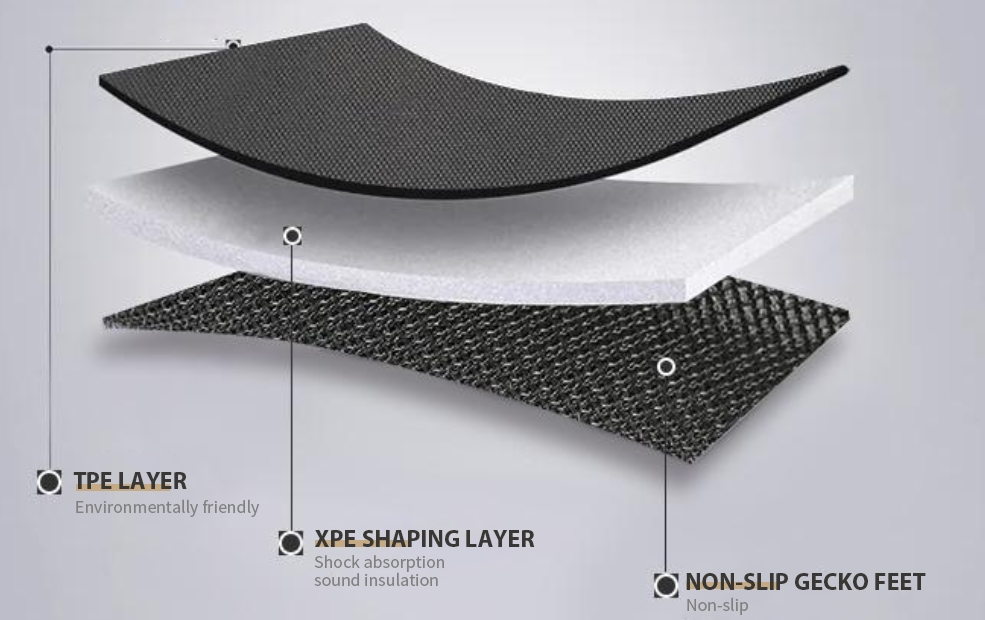

Gluebar’s TPE Hyundai car mats use a three-layer design. The top is eco TPE, the middle is XPE foam for shock absorption and soundproofing, and the bottom has an anti-slip layer. This setup is not only practical but also gives drivers peace of mind. At the same time, it follows today’s trend of recycling and sustainability.

Eco and Practical at the Same Time

Full coverage: Raised edges keep mud and water from spilling onto the carpet.

Waterproof and easy to clean: The surface layer is waterproof and can be rinsed clean with water.

No odor: Materials meet REACH rules and won’t release harsh smells.

All-weather ready: Works well from -30℃ to 60℃ without losing shape.

Unlike PVC, TPE mats are not just a product. They bring eco thinking into daily use. They make life easier for drivers and give buyers more confidence.

TPE Mats vs. Traditional PVC Mats

Eco: TPE is recyclable and harmless. PVC is being phased out in many markets.

Air quality: TPE has no odor. PVC often gives off smells.

Durability: TPE lasts longer. PVC ages faster and can crack.

Market outlook: TPE is growing fast in Europe and the U.S., while PVC is slowly leaving the stage.

For dealers, TPE fits the eco trend noted in the Polaris market research report. It also brings better acceptance in global markets. Choosing TPE Hyundai mats is like catching the future of the market early.

Luxury Car Floor Carpet: An Eco Upgrade for Comfort

Luxury and Eco Balance

In modern high-end cars, people want more than good looks. They also care about a healthy and eco-friendly interior. Premium car mats use a three-layer design: flocked fabric, XPE foam, and a non-slip base. This makes the ride more comfortable and avoids the smell and recycling issues of old carpet mats.

This shows that luxury and eco can go hand in hand. For buyers, these mats meet the needs of high-end clients without going against the trend of sustainability.

Eco Value in Comfort

Precise fit: 3D scanning reduces waste.

Healthy and safe: Non-toxic materials that don’t harm cabin air.

Sustainable: Durable and long-lasting, less need for replacement.

Quiet and smooth: Foam layer absorbs noise and reduces vibration.

These luxury car mats are no longer just simple accessories. They combine eco values with a premium feel. For distributors, they open the door to the high-end market while building an eco-friendly brand image.

Luxury Car Floor Carpet: Eco Mats vs. Traditional Carpet Mats

- Health: Eco composite materials, no smell. Traditional carpet mats trap dust and grow bacteria.

- Comfort: Composite layers are softer and block noise. Traditional carpet mats feel average.

- Durability: Composite mats are light and wear-resistant. Traditional carpet mats get damp and wear out fast.

- Sustainability: Eco mats can be recycled. Traditional carpet mats are almost impossible to reuse.

In other words, modern luxury car mats give drivers a premium feel while letting buyers face eco rules with confidence.

Sustainable Production Practices at the Factory

Eco TPE Materials to Reduce PVC Use

In making modern car mats, Gluebar uses eco-friendly TPE instead of traditional PVC. TPE is recyclable, non-toxic, and has lower emissions. It meets global standards like EU REACH. This choice eases the impact on the environment and helps car mats pass checks more easily in Europe, the U.S., and Asia. For dealers, it lowers compliance risks.

3D Scanning and Precise Molds to Cut Waste

Gluebar uses 3D scanning and high-precision molds to make car mats fit each model perfectly. This avoids the edge waste common in old methods. The European Environment Agency (EEA) notes that digital and smart manufacturing are key for the auto industry to save resources and go green.

Eco Quality Management

Gluebar follows ISO9001 and IATF16949 standards. This keeps production high-quality and eco-compliant. It ensures stable product performance and shows a long-term commitment to green manufacturing. For dealers, it means lower quality risks and stronger market trust.

Energy Saving and Waste Recycling

Gluebar uses energy-saving equipment to optimize heating and cooling, cutting power use. Waste from production is collected and reused, creating true resource recycling. The International Energy Agency (IEA) also stresses that recycling and low-carbon methods are key to emission goals in the auto supply chain.

See the factory and certifications here.

Eco Advantages for the Global Market

Meeting Strict Rules in Europe, the U.S., and Asia

When modern car mats are sold worldwide, they must pass different eco rules. Gluebar follows EU REACH, California VOC limits, and rising Asian standards in both design and production. This way, no matter where the mats are shipped, they clear customs smoothly and give dealers peace of mind.

OEM / ODM Eco Custom Services

Gluebar makes standard modern car mats and also supports OEM / ODM. From size design and material upgrades to custom brand marks, we offer tailored solutions while staying eco-compliant. This helps dealers stand out in tough markets.

See: OEM Car Floor Mats

Helping Partners Meet Market Entry Rules

In many regions, eco standards are the “entry ticket” to sell. Gluebar mats use eco materials, pass international tests, and follow strict quality control. This means partners don’t have to worry about returns or fines, while also building a strong, reliable brand image.

Future Outlook: Trends in Sustainable Car Mats

New Materials in Development

The focus for future mats will still be TPE (thermoplastic elastomer). TPE is recyclable, odor-free, and low-emission. It is replacing PVC and rubber as the choice for global car makers. It meets higher demands for health and eco standards, and it fits drivers’ push for greener travel.

Gluebar will keep improving TPE and explore new mixes, such as combining TPE with renewable fibers for lighter, lower-carbon mats. We also see the need for carbon neutrality. In the future, we will test degradable compounds or low-energy materials, so mats stay durable while cutting the carbon footprint.

Smart Manufacturing and Digital Potential

With Industry 4.0 growing fast, smart production is changing the car mat field. 3D scanning makes mats fit cars exactly, cutting waste. Digital modeling and automation shorten delivery times while keeping quality stable. Real-time data helps manage energy use and control emissions.

Together, digital tools and smart systems raise efficiency and make the eco value of mats measurable and easier to control. In the future, green manufacturing won’t be “extra cost” — it will be the key to competitiveness.

Gluebar’s Role in the Global Green Supply Chain

As a professional car mat maker, Gluebar will keep focusing on TPE mats. From front-row mats to trunk liners to high-end carpet mats, we aim for balance between eco, durability, and comfort. By using TPE and following ISO and IATF standards, we help global partners meet market rules and strengthen our role in the green supply chain of the future.