More and more car floor mat dealers are finding that standard products no longer meet market needs. Generic mats bring little profit and often fall into price wars. At the same time, different countries and regions keep raising the bar for eco-friendly materials and compliance. Without unique and customized products, dealers struggle to enter their target markets.

In this context, OEM (contract manufacturing) and ODM (design and branding) services have become a major focus. By working with a professional floor mat manufacturer, dealers can build their own brands while making sure the products meet global standards for materials, processes, and regulations. Let’s look at how manufacturers provide OEM / ODM services and the real value this model can bring to dealers.

Why car dealers need OEM and ODM

Build your own brand

If a dealer only sells generic mats, customers won’t remember them. OEM and ODM services make it possible to have a brand of their own.

From design to packaging, everything can be customized.

- It highlights personality and style.

- Customers are more likely to remember and choose branded products.

- It’s not just selling products, but also building reputation and long-term value.

Escape the price war

Floor mats are a must-have, but they are often too similar. Most products look the same, and competition is based only on price. OEM / ODM helps dealers break free from this trap.

- Custom products stand out, no need to fight only on low price.

- Can meet different needs, like eco-friendly materials or car-specific fit.

- Differentiated design makes products worth more.

Stay compliant and enter markets

Export markets have strict rules on eco and quality. If products don’t pass, they may get returned or fined. Working with an experienced manufacturer reduces these risks.

- Products meet international standards and enter markets in the US, EU, Asia with ease.

- Avoid losses or brand damage from non-compliance.

- Testing and reports lower compliance risks.

The Core Difference Between OEM and ODM

OEM and ODM may sound alike, but for dealers they are two very different ways of working. Knowing the difference helps them pick the best option.

OEM: Contract Manufacturing

In OEM, the dealer provides the design and specs, and the manufacturer only handles production.

This model fits dealers who already have their own brand and understand market needs.

- Dealer leads design: full control of look and function.

- Manufacturer focuses on production: stable scale and quality.

- Lower production costs: works best for dealers with steady channels and sales.

ODM: Design and Branding

In ODM, the manufacturer offers a one-stop solution from design to finished product. Dealers only need to share their idea, and they get a ready-to-sell product fast.

- Manufacturer handles R&D: completes design and process.

- Save R&D costs: good for dealers without a design team.

- Faster market entry: less time, quicker launch.

How Dealers Decide

Choosing OEM or ODM depends on market position and resources. If a dealer already has a brand and clear product plan, OEM is the way to go. If the goal is to cut R&D risks and launch unique products faster, ODM makes more sense.

Core Services From Manufacturers

A strong floor mat manufacturer is more than a supplier. They act as a partner behind the dealer. OEM and ODM cover the whole process from materials to delivery, so dealers can focus on sales without worrying about the supply chain.

Material Selection and Eco Options

Modern floor mats have moved past PVC. Eco materials are now the standard. Manufacturers provide green choices based on market and customer needs.

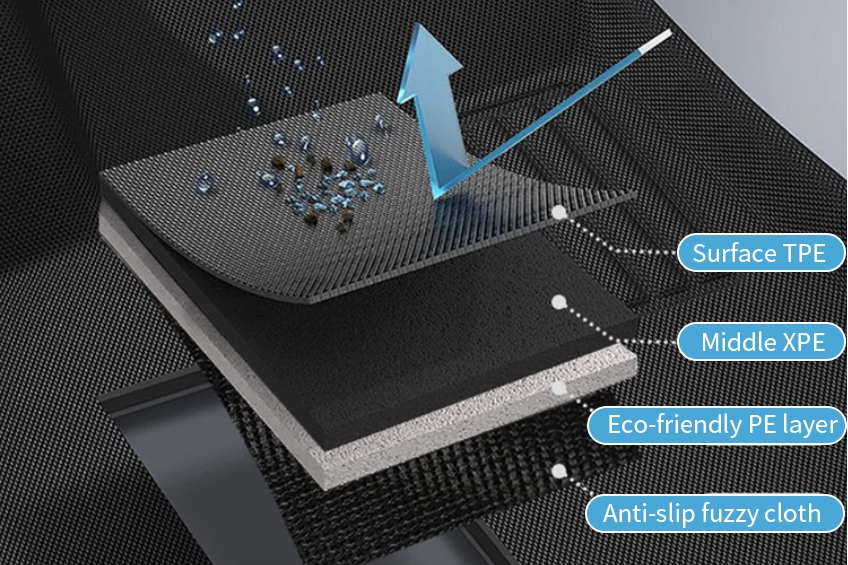

Eco TPE: recyclable, odor-free, low emission, aligned with global rules.

XPE foam layer: lightweight, noise-absorbing, shock-reducing, great for comfort mats.

For dealers, it’s not just about picking a material. It’s about picking market competitiveness.

Structure Design and Function Upgrades

A floor mat is more than just a mat. It needs precise fit and useful features. With 3D scanning and car-specific molds, manufacturers create unique designs.

- Precise fit: custom to each model, no slipping.

- Feature upgrades: raised edges keep mud and water in, surface is waterproof and easy to clean.

- Global use: withstands -30℃ to 60℃ for different climates.

This makes products both practical and appealing.

Packaging and Brand Display

OEM / ODM isn’t only about production. Packaging is also a key part of branding. Manufacturers can design complete brand display solutions.

- Custom packaging: fits different styles and market needs.

- Multi-language labels: ready for exports, adds professionalism.

- Manuals and brand cards: build trust and strengthen brand image.

Good packaging doesn’t just protect products—it markets them.

Process Upgrades and Unique Features

In a crowded market, small details make a big difference. Manufacturers use process innovation to add unique value to mats.

Quiet layer: reduces cabin noise for more comfort.

- Wear-resistant coating: longer product life, less frequent replacement.

- Lightweight design: easier transport, lower shipping costs.

These features make the dealer’s products easier for markets to remember.

See the car mat manufacturing process [https://www.gluebarcarmat.com/product-know-how/car-mat-manufacturing-process.html].

Compliance and Market Access

Different countries have different eco and safety standards. For a dealer, handling them alone means high risk and cost. Manufacturers provide full compliance support.

- International certifications: REACH, VOC, ISO9001, IATF16949.

- Compliance testing: reports to ensure smooth entry into US, EU, and Asia.

- Local adaptation: designs adjusted to local rules and habits.

This way, dealers can focus on market growth without worrying about compliance risks.

How to Ensure Quality and Compliance

Eco and Quality Standards

Reliable manufacturers strictly follow global eco and quality standards. This makes it easier for products to enter overseas markets. For dealers, it’s not only compliance—it’s also confidence when talking with customers.

Precise Production and Smart Manufacturing

With 3D scanning and digital molds, mats fit cars with precision. Automation makes production faster, reduces material waste, and ensures stable delivery times.

Full Testing and Quality Control

Before shipping, mats go through tests like wear, slip resistance, temperature, and odor checks. This ensures products are practical and safe. Dealers can sell with confidence, without worrying about after-sales issues.

Stable Supply and After-Sales Support

Experienced manufacturers usually provide steady delivery times and flexible minimum order quantities. They also offer technical support and warranties after sales, giving dealers a stronger supply chain.

Recommended reading: Key Certifications Every Car Mats Manufacturer Should Have

The Value of OEM / ODM

Brand Differentiation

In a crowded market, dealers need their own brand to stand out. OEM / ODM services help shape the brand through product design, packaging, manuals, and brand story.

- Products no longer look generic but carry a clear “signature.”

- Increases customer memory and loyalty.

- Builds long-term barriers, less risk of being replaced by cheap products.

Lower R&D Costs

For dealers without a design team, ODM is the easiest option. Manufacturers provide ready-made solutions. Dealers just confirm needs and get the product fast.

- Saves R&D investment, avoids labor and equipment costs.

- Uses proven designs, reduces trial-and-error risks.

- Shortens launch cycle, captures market opportunities faster.

Expand to Multiple Markets

Each region has different needs. OEM / ODM adjusts to local rules and customer habits.

- Canada: strict eco laws, focus on odor-free and cold resistance.

- Europe (Germany, UK, France, Italy): want eco plus premium feel, prefer luxury design and green materials.

- Australia: varied climate, need mats that resist heat, water, and slips.

- Southeast Asia (Malaysia, Indonesia): value price and easy cleaning, lightweight mats are popular.

- Brazil: growing market, focus on balance of durability and price.

- India (Madhya Pradesh, Rajasthan, Uttar Pradesh, Bihar): fast-growing market, small dealers use ODM to launch products quickly.

Dealers don’t need to research each market in detail. They can launch the right products fast.

Build Long-Term Partnerships

OEM / ODM is not a one-time deal but a long-term relationship. A reliable manufacturer supports dealers in supply, design, quality, and after-sales.

- Stable supply chain avoids stock shortages.

- Quality assurance reduces after-sales stress.

- Grow together with the manufacturer, building trust and helping expand markets.

Case Studies and Future Trends

Success in Overseas Markets

- In Europe, dealers launched TPE mats for Germany and France through OEM. They passed eco tests and entered major retail channels.

- In Canada, ODM eco mats became popular for being odor-free and cold-resistant.

- In Australia, ODM custom mats with waterproof and sun-proof designs met climate needs.

- In India, small dealers used ODM branding to enter auto parts markets in new cities and expand quickly.

These cases show that OEM / ODM not only helps meet market rules but also captures local trends.

Eco Materials and Green Upgrades

Eco materials are the future. TPE will stay mainstream, combined with recycled fibers and low-carbon materials. The result: lighter, greener mats. This meets regulations and helps dealers build a “green brand” identity.

Smart Manufacturing Trends

With Industry 4.0, manufacturers use automation and digital tools. This makes mat customization faster, more stable, and reduces energy and waste. For dealers, it means getting market-ready products quicker.