In the auto parts industry, choosing a long-term floor mat manufacturer is not just about finding a factory that can deliver. It’s about picking a strategic partner who can grow with you. Many clients first think about price, but the real factors that make a partnership last go far beyond quotes.

So, how do you know if you’ve found the right long-term partner? At least seven points need to be checked:

- Can the factory scale support long-term cooperation?

- Does the manufacturing process have advanced and stable methods?

- Is there a solid quality control system with certifications?

- Can customization meet different market needs?

- Are there enough proven cases to show factory strength?

- Are delivery and after-sales reliable?

- Does the manufacturer have long-term growth potential?

Let’s go through them one by one.

1. Can the factory scale support long-term cooperation?

Factory size and equipment investment

Stable capacity is the base of long-term cooperation. A factory with enough space and advanced equipment can handle orders of different sizes without delays when demand rises. Gluebar owns a 27,000 m² modern plant with complete facilities, including mold making, hot-press forming, and laser scanning. This ensures mass production and fast delivery. For partners, this means peace of mind to expand without worrying the factory will fail at key times.

Employee size and production teams

The size and stability of the workforce determine if supply can be sustained. An experienced and well-organized team keeps lines efficient, whether during regular orders or peak season surges. Gluebar has 300+ employees, with production teams arranged to flexibly adjust resources. For partners, this means even sudden demand can be met with stable supply.

Annual and monthly capacity

Stable yearly output and flexible monthly supply are critical for long-term partnerships. If capacity is weak, customer channels and reputation suffer. Gluebar produces over 1.5 million sets per year and adjusts monthly schedules as needed. This supports both large steady orders and phased deliveries. Such supply strength helps partners seize market chances and avoid the risks of stock shortages.

2. Does the manufacturing process have advanced and stable methods?

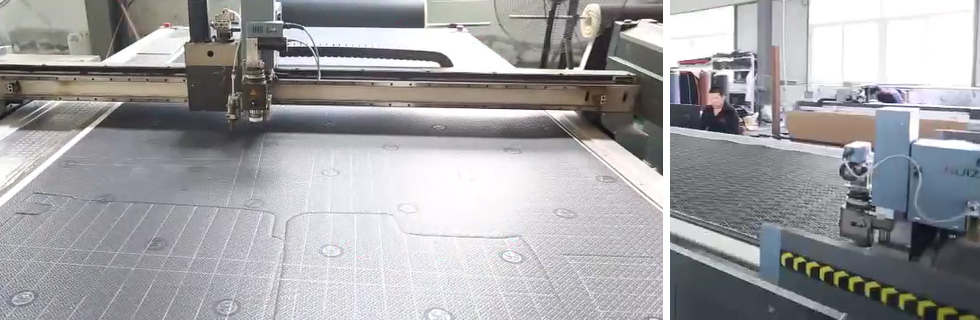

Advanced processes like hot-press forming

Process level decides product quality and lifespan. A strong long-term partner must go beyond basic production and use advanced methods to ensure consistent output. Gluebar uses hot-press forming, which makes mats fit car floors tightly, avoiding shifting or curling. It also strengthens durability, keeping mats in shape even with long use. For partners, this means offering high-end, reliable products with fewer after-sales risks.

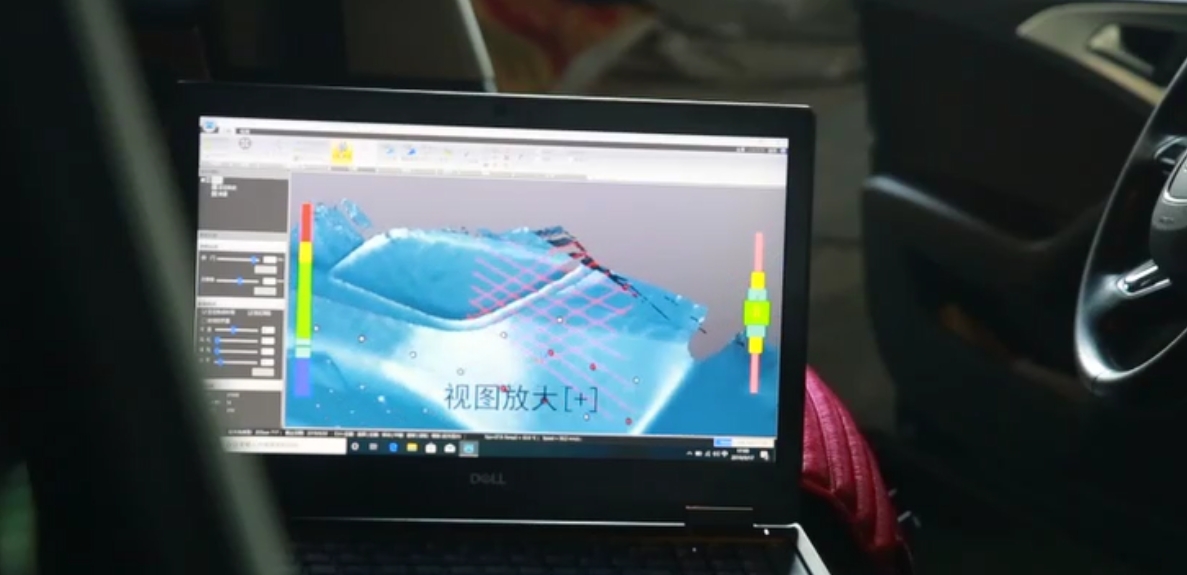

Laser scanning and 3D modeling for customization

Advanced tools are key for meeting diverse market needs. 3D laser scanning and modeling ensure mats fit each car model with precision. Gluebar has a large database of thousands of models, so they can react fast to new car launches. This technical reserve not only guarantees accuracy but also gives clients a first-mover advantage in the market.

Ull coverage of all-weather performance

The market demands more than just “a mat.” It expects full performance: waterproof to handle rain and snow, anti-slip for driving safety, wear-resistant for longer use, and eco-friendly TPE that meets global green standards. Gluebar focuses on eco TPE mats—odor-free, easy to clean, and stable in both hot and cold climates. For clients, these high-performance mats mean better user satisfaction and fewer returns, building a stronger long-term relationship.

3. Does the factory have a quality system and certifications?

Has the factory passed ISO9001 and IATF16949?

In the auto parts industry, certifications are more than papers. They show the factory’s overall strength. ISO9001 means a standardized quality system, while IATF16949 is the strict entry barrier for the auto industry. A factory with these proves its management, production, testing, and supply chain have been reviewed by authorities. Gluebar has passed ISO9001 and IATF16949, meeting compliance needs of the global auto supply chain.

Does the factory have authoritative product test reports and certificates?

A long-term partner should prove reliability with reports and data. Beyond basic physical tests, there should also be third-party certifications, such as wear tests, aging tests, slip resistance, and VOC eco tests. Gluebar mats meet international eco and safety standards and have complete reports ready for clients. This helps avoid legal and quality risks.

Does it have strict quality traceability and inspection processes?

A stable quality system requires strict traceability. A professional factory should check every step—from raw materials, to semi-finished, to final shipment. Gluebar follows a triple inspection: incoming material checks, in-process sampling, and full final inspection. Each batch also has trace records to quickly locate problems and solutions. This system reduces after-sales risks and protects client reputation.

4. Can customization meet market needs?

Does it support custom brand logos and packaging?

In long-term cooperation, customization is often one of the most important services for clients. Gluebar can provide many forms of branding support, such as nameplates, custom packaging design, instruction cards, and manuals. These help clients build a clear brand identity and add product value.

It’s important to note that logo customization here refers to the client’s own brand mark (Customer Brand Logo Service), such as a dealer or wholesaler logo, to strengthen brand power in the market. Automaker logos (like BYD, Geely) can only be used in OEM projects with carmakers, as respecting brand licensing is a basic rule in international cooperation.

Can it provide multi-language labels and manuals?

When entering overseas markets, language and localization are often the first barriers. Gluebar can provide multi-language labels and manuals based on target market needs, such as English, French, Spanish, and Arabic. This not only saves clients the cost of translation and printing, but also helps products adapt faster to local markets.

Can it meet the different needs of North America, Europe, and Asia?

Consumers in different regions have very different expectations for mats. The North American market focuses more on eco certifications and compliance. The European market values design and safety performance. The Asian market pays closer attention to cost-effectiveness and practicality. Gluebar understands the features of each region and can flexibly adjust material choices, process standards, and design details. This ensures products meet local rules and also match consumer preferences, helping clients stay competitive worldwide.

5. Do case studies prove the factory’s strength?

Has it built long-term partnerships with automakers (OEM)?

Joining an OEM supply system is the highest recognition of a factory’s strength. OEMs set very strict requirements for suppliers, from production standards and quality systems to delivery capacity. Gluebar has built long-term stable partnerships with automakers like BYD, Geely, Great Wall, and JAC, and has supplied multiple car models. This proves the factory’s manufacturing level and quality control ability, and gives new clients more confidence.

Has it built long-term partnerships with automakers (OEM)?

Joining an OEM supply system is the highest recognition of a factory’s strength. OEMs set very strict requirements for suppliers, from production standards and quality systems to delivery capacity. Gluebar has built long-term stable partnerships with automakers like BYD, Geely, Great Wall, and JAC, and has supplied multiple car models. This proves the factory’s manufacturing level and quality control ability, and gives new clients more confidence.

Does it have a large number of stable long-term clients?

The number of long-term clients is a key measure of trust. Gluebar mats are now sold in more than 2,000 auto sales and service outlets, forming a wide and stable customer network. Long-lasting partnerships show the factory is consistent in supply, quality, and service, and that it values long-term reputation over short-term gain.

6. Are delivery and after-sales reliable?

Are standard delivery times under control?

In today’s competitive global supply chain, delivery speed directly affects client performance. Gluebar sets clear standards: 15–20 business days for mass production and only 5–7 days for sample development. This fast and steady schedule helps clients launch products quicker and avoid losses from delays.

Does it support direct overseas supply and multiple delivery terms (EXW, FOB, CIF)?

International clients often need flexible shipping options. Gluebar supports EXW, FOB, and CIF, with an experienced export team to handle customs and transport. Whether full-container sea freight or small-batch air freight, clients get reliable service Incoterms® 2020 – ICC.

Does it provide ongoing after-sales technical support and fast response?

After-sales service is the lubricant of long-term partnerships. Gluebar has a quick-response system for installation, transport, or quality issues. Clients get solutions right away, reducing risks in daily operations and making cooperation more stable over time.

7. Does the manufacturer have long-term growth potential?

Has the company focused on the car mat industry for many years?

Time is proof of strength. Gluebar’s predecessor was founded in 1996, and for nearly 30 years it has focused on R&D and manufacturing of car mats. This focus has built deep experience in process and technology. It also means the company will not easily switch fields or abandon this industry. That makes it a trustworthy long-term partner.

Does it keep investing in R&D and product upgrades?

Market demand is always changing. Clients don’t just need “unchanging products” but solutions that keep improving. Gluebar has its own R&D team and invests every year in new materials, structure design, and eco performance. This keeps its products competitive worldwide. For example, in TPE applications and hot-press forming, Gluebar has built clear industry advantages.

Does it have a global market layout and brand strategy?

A global presence is a sign of long-term growth. Gluebar not only has stable domestic partners but also export channels in North America, Europe, and Southeast Asia, forming a worldwide market network. For clients, this means the factory can meet today’s orders and also support future international business expansion.

Conclusion

When choosing a long-term car mat manufacturer, price is only a reference. The real evaluation comes from many angles: factory scale, manufacturing process, quality system, customization, case studies, delivery, and growth potential.

Gluebar, with 1.5 million annual capacity and global service, stands on quality and wins with service. With advanced processes, strict quality control, and rich international cooperation, it provides reliable long-term support. Looking ahead, Gluebar will keep investing in R&D and global expansion to be a trusted partner worldwide.