Many people encounter a question when buying or exporting car floor mats: "Is this a left-hand drive or right-hand drive floor mat?" It may seem like just a difference in whether the steering wheel is on the left or right, but this is actually very important for floor mats.

1. What are left-hand drive and right-hand drive? Why are car floor mats also differentiated?

The "rudder" of a car refers to the position of the steering wheel. Different countries have different driving directions, resulting in the distinction between "left-hand drive" and "right-hand drive" cars. This is not only a matter of driving habits, but also affects the vehicle's internal structure, especially the design and fit of the car floor mats.

Left-Hand Drive Floor Mats: Precise Design for the Mainstream Market

Left-Hand Drive (LHD) vehicles are the most common type of car globally, used in countries such as China, the United States, Germany, and France. In these vehicles, the steering wheel is on the left, the vehicle drives on the right, and the driver controls the accelerator with their right foot and the brake with their left. This means that the structure of the driver's seat floor, the angle of the accelerator pedal, and the position of the footrest recess are all biased towards the right side.

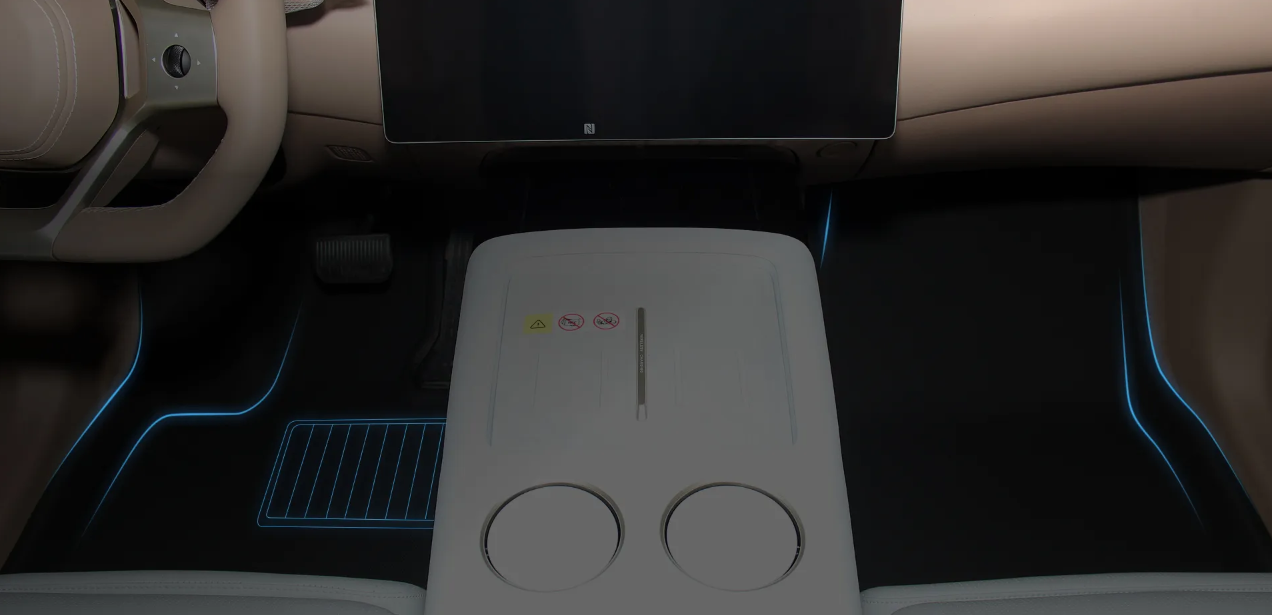

When designing left-hand drive car floor mats, Gluebar uses 3D laser scanning technology to accurately acquire floor data and create a model of the original vehicle chassis. The floor mats in the driver's area are often reinforced with a stronger right foot support, featuring anti-slip ribs and a high-density TPE layer to ensure stability during frequent acceleration and braking. The passenger side and rear floor mats prioritize extensibility and spatial continuity, ensuring a seamless finish that is both neat and safe.

Right-Hand Drive Floor Mats: Reverse-Customized for Commonwealth and Asian Markets

Right-hand drive vehicles (RHD) are common in countries such as the UK, Australia, Japan, Malaysia, and India. These vehicles have the steering wheel on the right and drive on the left, so the overall chassis structure is a complete mirror image of left-hand drive vehicles. Using left-hand drive floor mats directly would result in issues such as misaligned accelerator pedal position, misaligned clips, and raised edges.

Gluebar rescans, independently models, and molds the mats specifically for right-hand drive vehicles.

For example, in right-hand drive vehicles, the driver's high-wear area is on the left foot, so the anti-slip zone, pedal protection lines, and bending curves are reversed. In terms of edging design, Gluebar adjusts the outer edge angle of the floor mats to perfectly fit the right-side door sill and pedal edge, preventing water or sand spillage.

For example: Same Mercedes, Different Floor Mats

Take the Mercedes-Benz C-Class as an example. The version sold in China and Germany is for left-hand drive, while the version sold in the UK and Australia is for right-hand drive. Although the model name is the same, the floor mats are completely different:

The left-hand drive version's accelerator pedal protection area is on the right side;

The right-hand drive version's protection area is on the left side;

The clips, fixing points, and curved edges are all mirror images.

Gluebar engineers use two mold systems in the factory to verify the fit separately.

From scanning, cutting, heat pressing to quality inspection, each floor mat undergoes independent testing to ensure "original car-level fit" regardless of the market it's sold in.

II. Which countries use left-hand drive and which use right-hand drive?

Driving rules differ from country to country, and so do steering wheel positions.

This may seem like just a driving habit, but it represents a "structural difference" for car floor mats—because the positions of the driver's seat, accelerator, and brake are all reversed, floor mats must be produced using different molds for left-hand drive and right-hand drive vehicles.

Let's look at the global distribution by region.

North America: Primarily Left-Handed

Countries like the United States, Canada, and Mexico use left-hand drive vehicles, with the steering wheel on the left and vehicles driving on the right.

Car floor mats in these countries are generally designed for left-hand drive, with the driver's side anti-slip zone positioned at the right foot.

When producing floor mats for the North American market, Gluebar reinforces the right foot pressure zone and adds high edge coverage to ensure the mats don't shift during high-speed driving.

Europe: Predominantly Left-Handed, with the UK as an Exception

Most European countries, such as Germany, France, Italy, Spain, Poland, Belgium, the Netherlands, and Russia, use left-hand drive.

However, the UK and Ireland are right-hand drive countries, driving on the left.

This means that even for brands like Mercedes-Benz or Volkswagen, the European market uses two different floor mat molds: left-hand drive versions for Germany and France, and right-hand drive versions for the UK and Ireland.

Asia: Left- and Right-Hand Drive Coexist, China Also Has a Dual System

Asia is one of the most complex regions.

Countries like mainland China, South Korea, India, and Vietnam use left-hand drive systems, while countries like Japan, Thailand, Malaysia, Indonesia, the Philippines, and Singapore use right-hand drive systems.

It's worth noting that Hong Kong and Macau are right-hand drive regions, similar to the UK's transportation system.

This means that when supplying the Chinese market, Gluebar needs to maintain both left-hand and right-hand drive mold versions to serve dealers in different regions and cross-border customers.

The same car model, such as the Toyota Camry, is produced in a left-hand drive version in mainland China, but exported to Hong Kong or Southeast Asia as a right-hand drive version.

Floor mats must be redesigned – the accelerator anti-slip zone, buckle holes, and the angle of the door sill trim must all be "mirror-reversed."

Oceania: Primarily Right-Hand Drive

Australia and New Zealand are both right-hand drive countries.These countries mainly produce British-made vehicles, and their floor mat molds also follow British standards.

When producing right-hand drive floor mats, Gluebar designs the snap-fit holes and edge angles in reverse to ensure stability and slip resistance when the driver is operating on the right side.

Africa: Significant North-South Differences

Africa is a unique region. South Africa uses right-hand drive, while countries like Nigeria and Egypt use left-hand drive.

This means that versions of the same car brand can vary greatly from country to country.

When Gluebar exports its floor mats to Africa, they confirm the drive type based on the customer's country to prevent size or clip incompatibility.

South America: Primarily Left-Handed

South American countries such as Brazil, Argentina, Chile, and Colombia generally use left-handed drive systems.

Gluebar's floor mats exported to the Latin American market are primarily left-handed, with mold specifications similar to those in North America. The main differences lie in the buckle specifications and material preferences.

III. Differences in the manufacturing process between left-hand drive and right-hand drive floor mats

At Gluebar's factory, the production lines for different steering wheel types of floor mats resemble two parallel roads—they look similar, yet each goes its own way in every detail. The difference between left-hand and right-hand drive isn't just about the left and right sides of the steering wheel; it's a comprehensive distinction from molds and structure to testing methods.

Whenever a new car model enters development, the engineers always ask, "Is this left-hand or right-hand drive?" because this will determine the direction of the entire production process.

1. Different Mold Structures

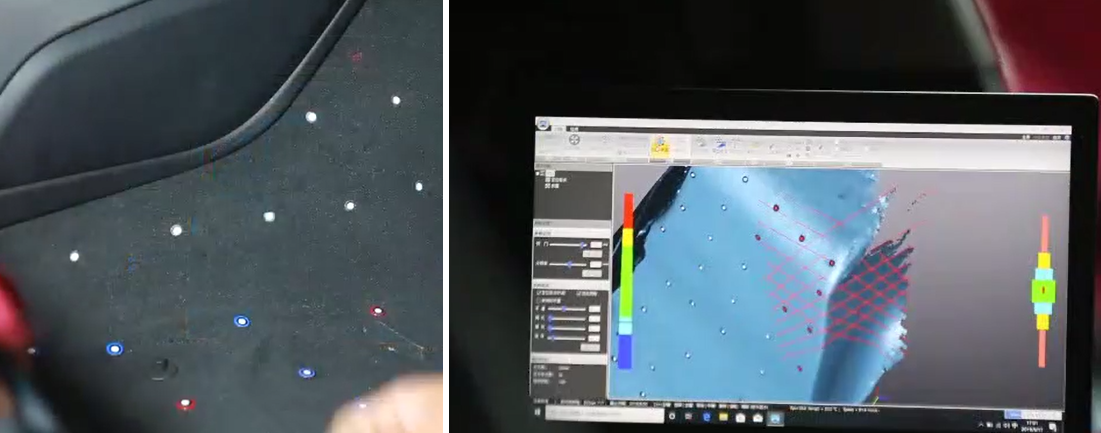

In the 3D scanning room, engineers are using laser equipment to record every detail of a vehicle's chassis. Two sets of images are displayed side-by-side on the screen—the structure of a left-hand drive vehicle extends to the right, while that of a right-hand drive vehicle is reversed like a mirror image. It is this seemingly minor structural difference that makes it impossible to use the same mold for the floor mats. Gluebar's mold makers create molds independently based on the scanned data of the actual vehicle, ensuring that every curve and every clip position precisely matches the original vehicle data. Even for the same Mercedes-Benz model, if the steering wheel type is different, a new mold must be created. This "mirror-image manufacturing," while complex, ensures that the floor mats fit perfectly against the vehicle's floor, without lifting edges, pressing against the feet, or interfering with pedal operation.

2. Different Reinforcement in Pedal Areas

At the design station, another team of engineers is adjusting the reinforcement structure of the driver's area. Left-hand drive drivers primarily control the accelerator and brake with their right foot, while right-hand drive drivers do the opposite, resulting in different pressure zones. To extend the lifespan of the floor mats and improve safety, Gluebar adds thicker layers, anti-slip ribs, and wear-resistant textures to key areas, tailored to the stress characteristics of different steering wheel types. Each material adjustment undergoes repeated friction and foot-step tests to ensure the floor mats remain stable and supportive under any driving action. For Gluebar, this is not merely an adjustment to the product structure, but a precise response to driving safety.

3. Different Fastener and Inspection Standards

In the quality inspection area, workers are inspecting two sets of floor mats that look almost identical. One is for left-hand drive vehicles, and the other is for right-hand drive vehicles. The fastener positions for different drive types are usually mirror images—left-hand drive models usually have them on the right side of the driver's seat, while right-hand drive models have them reversed. Gluebar's quality inspectors check the position of each fastener to the floor anchor point to ensure that the installation is secure, does not shift, and does not interfere with accelerator and brake operation. Every millimeter on the inspection table must precisely correspond to the actual vehicle parameters. If any error is found, the entire set of floor mats will be returned for re-drilling. Only products that pass through layers of inspection can enter the packaging stage and be shipped all over the world—whether it's a right-hand drive sedan in Tokyo or a left-hand drive SUV in Berlin, Gluebar floor mats fit securely.

IV. How to choose the right steering wheel-shaped car floor mats?

Confirming the Vehicle's Steering Wheel Type

Determining the steering wheel type is actually quite simple—a vehicle with the steering wheel on the left and driving on the right is a left-hand drive (LHD) vehicle, while a vehicle with the steering wheel on the right and driving on the left is a right-hand drive (RHD) vehicle. Generally speaking, most countries in mainland China and Europe and America use left-hand drive, while countries such as the UK, Australia, Malaysia, and Japan generally use right-hand drive. To confirm, check the vehicle's nameplate or factory specifications, which will clearly indicate LHD or RHD.

During the factory design phase, Gluebar engineers determine the steering wheel direction based on the vehicle model and target market during the drawing stage. This ensures consistency in subsequent mold making, cutting, heat pressing, and clip positioning. This step determines the starting point of production and whether the floor mats can ultimately fit the vehicle's floor perfectly.

Providing Accurate Vehicle Model Information

For dealers, distributors, or OEM customers, providing complete vehicle model information is the first step in ensuring the matching accuracy of floor mat production.

When placing an order or establishing a cooperation agreement, the following parameters should be clearly provided: brand, vehicle model, year, and steering wheel type (LHD/RHD).

For example:

Toyota Corolla 2022 LHD (Left-hand drive)

Toyota Corolla 2022 RHD (Right-hand drive)

Gluebar possesses a 3D chassis database covering major global vehicle models. Each vehicle model and each steering wheel type has a unique number and mold file. Upon receiving order information, the engineering department automatically matches the mold based on the vehicle parameters provided by the customer and generates a production task. This systematic management ensures that even different regional versions of the same vehicle model can be quickly distinguished and accurately produced.

During the mass production stage, Gluebar will double-check the steering wheel type data to prevent mismatches caused by left/right-hand drive confusion. For export orders, the system will also automatically mark the destination country's steering wheel standard (e.g., RHD for the UK and Australia; LHD for Germany and the US) to ensure that the products shipped in batches are completely consistent with the local vehicle structure.

Why can't "universal" floor mats be used?

Some products on the market are labeled "universal," but for professional manufacturing, this is practically a non-existent concept. The floor structure of left- and right-hand drive vehicles is mirror-image; the buckle positions, anti-slip rib directions, and footrest shapes are completely different. Even using the same materials, if the mold orientation is incorrect, the floor mats will not fit properly and may even pose safety hazards.

Gluebar insists on independently modeling and testing each steering wheel type, refusing to substitute "universal" for "precision." This precision not only reflects manufacturing strength but also respect for the brand and the end market.

How can Gluebar support both left-hand and right-hand drive versions?

Dual Tooling System: Ensuring Precise Fit for Every Market

In the global automotive market, vehicle structures vary depending on the driving orientation. The floor shape, clip positions, and pedal area differ between left-hand-drive and right-hand-drive models. To address this, Gluebar developed a Dual Tooling System during the design phase, ensuring that each vehicle model has independent molds for both left-hand and right-hand versions.

From left-hand-drive Mercedes models to right-hand-drive vehicles for the Australian market, Gluebar conducts 3D laser scanning and reverse modeling to achieve millimeter-level precision in curvature, edge coverage, and clip-hole positioning.

This approach ensures that floor mats perfectly fit the cabin structure of every model while maintaining consistent global manufacturing standards.

Smart Recognition and Factory Labeling for More Efficient Delivery

During the production stage, Gluebar’s system automatically identifies LHD/RHD model codes and activates the corresponding molds for manufacturing. Each batch of floor mats is clearly labeled with its steering orientation during packaging, preventing any mix-up or incorrect shipment between left-hand-drive and right-hand-drive versions.

For export orders, the system automatically matches the steering type based on the destination country — for example, LHD for shipments to Germany and the United States, and RHD for those to the United Kingdom, Malaysia, and Australia. This streamlined process enables global distributors to place orders with confidence, ensuring that no matter where the mats are delivered, every set fits perfectly upon installation and every shipment is accurate.

Whether you drive on the left or the right side, Gluebar hopes that when you step onto the mat, you feel more than just grip and support — you feel a sense of comfort and trust beneath your feet.