Chinese OEM car floor mat factories have become the most relied-upon supply force for global brands, with their core competitiveness stemming from three major advantages: a mature system, comprehensive capabilities, and stable delivery. Chinese manufacturers hold leading positions in the industry in TPE material processing, vehicle model data accumulation, hot-pressing production technology, and large-scale manufacturing capabilities, enabling them to simultaneously meet the product standards most valued by global brands, such as environmental performance, fit precision, and year-round climate adaptability. More importantly, Chinese factories possess a complete OEM/ODM service system for car floor mats, efficiently coordinating from vehicle model development and packaging design to branded production, making it easier for overseas brands to establish themselves in different car floor mat markets for the long term.

Reason 1: A complete and mature supply chain system

The TPE raw material, mold, and equipment supply chain is highly concentrated in China.

China boasts a complete automotive floor mat manufacturing industry cluster, with TPE raw material plants, mold factories, and thermoforming equipment manufacturers all located domestically. This highly concentrated supply chain structure allows for rapid completion of material procurement, mold development, and equipment upgrades, significantly reducing production and communication costs.

Centralized development chain enables faster and more cost-effective vehicle development.

Due to the complete supply chain, factories can quickly complete vehicle scanning, mold making, material verification, and molding testing locally. This means that new products can be completed in a shorter cycle from "data → mold → product," accelerating time-to-market and making the overall development cost more competitive.

Global brands are willing to entrust new products to Chinese factories because of their faster response times.

For overseas brands, with rapid new model updates and intense market competition, the quick response capabilities of car floor mat suppliers are crucial. Chinese car floor mat factories, with their mature supply chains and efficient collaboration, can complete trial production and verification of new products in a short period, thus becoming the preferred partners for many brands' new product development.

Structural Advantages Unmatched by Overseas Factories

In contrast, many overseas manufacturing locations lack complete raw material, mold, and equipment support, requiring cross-border coordination, resulting in long development cycles and high costs. China's integrated supply chain capabilities for automotive floor mats give it a natural advantage in speed, cost, and flexibility, which is a key reason why global brands have long chosen Chinese OEMs.

Reason 2: A robust vehicle database and excellent fit.

Covering major global car models, with wider compatibility

Over the years, Chinese car floor mat manufacturers have built a comprehensive database of car models covering the global market. Whether it's SUVs, sedans, or the rapidly growing new energy vehicles, they possess corresponding scanning data and mold reserves. For global car floor mat brands, broad model coverage means faster entry into more markets and improved sales efficiency.

Supports Year-Specific Differences and LHD/RHD for More Precise Adaptation

Different car models from different years may have subtle variations in their floor structure, and the database of Chinese car floor mat factories can accurately distinguish these structural differences from year to year. Simultaneously, it supports the development of both left-hand drive (LHD) and right-hand drive (RHD) markets, ensuring that car floor mat products not only cover the global market but also accurately match local driving habits.

1:1 Laser Scanning Technology for a Guaranteed Fit

Advanced 3D laser scanning technology captures the details of the original car floor, achieving a true 1:1 fit. Precise terrain texture data ensures a stable, non-slip, and non-lifting fit for the molded floor mats, significantly improving the user experience while reducing repair rates and after-sales risks.

Chinese factories have a clear advantage in fit and stability

For overseas brands and dealers, whether car floor mats fit well is the most crucial quality standard and their biggest concern. Chinese manufacturers have a natural advantage in vehicle model data accumulation, mold precision, and scanning technology, resulting in more stable and reliable fit and adhesion. This is one of the key reasons why global brands are willing to cooperate with Chinese factories long-term.

Reason 3: Stable and reliable TPE environmentally friendly materials

odorless performance better meet car owners' requirements for in-car air quality.

High-quality TPE materials naturally offer low-odor performance. After strict raw material selection and formula optimization, they can achieve near-odorless product performance. This is especially crucial for markets in Europe, America, the Middle East, and Australia that emphasize VOC levels, and is one of the most important basic conditions that car floor mat dealers consider when selecting suppliers.

Stable performance in high and low temperatures

TPE material maintains its flexibility within a temperature range of -40°C to 80°C, without hardening, deforming, or cracking. This makes it suitable for cold regions (Canada, Northern Europe), high-temperature regions (Middle East, Australia), and markets with large temperature differences, which is an important reason why global brands choose TPE car floor mats.

TPE material offers excellent deformation resistance.

Compared to traditional PVC or rubber, TPE has better structural strength and resilience. It is less prone to warping, collapsing, or permanent deformation after prolonged use, maintaining a stable fit and anti-slip performance for long-term car floor mats and reducing after-sales issues.

Compliant with global environmental regulations

TPE is a recyclable and environmentally friendly material that contains no heavy metals and does not release harmful volatile organic compounds, meeting the environmental standards of European and American markets. As global consumers increasingly focus on environmentally friendly materials, TPE car floor mats are gradually replacing PVC and rubber, becoming the mainstream choice.

Reason 4: Large-scale automated production capabilities

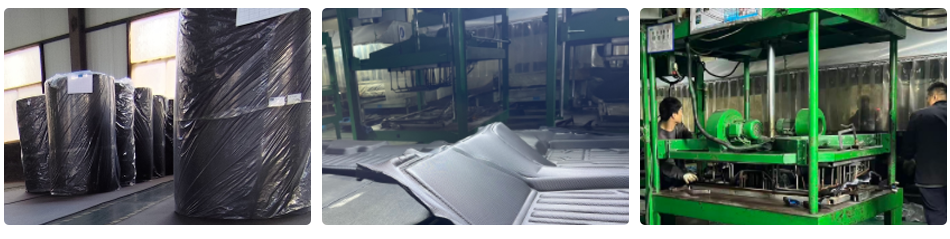

Multi-million annual production capacity provides long-term supply assurance for brands.

Chinese car floor mat factories generally possess large-scale production capacity, with established suppliers capable of producing millions of units annually. This means that whether it's large orders during peak seasons, annual procurement plans, or the long-term replenishment needs of regional distributors, stable production capacity can support these needs, preventing stockouts or insufficient production.

Automated Hot Press Production Lines Enhance Efficiency and Consistency

Leading car floor mat factories are equipped with automated hot pressing molding equipment, significantly improving production efficiency while maintaining consistent product quality—cleaner edges, clearer textures, and more stable dimensions. Automated processes reduce human error, ensuring stable dimensions and fit for car floor mats during mass production.

Support for Periodic Replenishment

For overseas distributors, continuous replenishment and inventory turnover are crucial. With its mature production scheduling capabilities and flexible planning management, the Chinese factory can support customers' periodic replenishment needs, ensuring sufficient supply under different market strategies.

High consistency reduces after-sales risks

Automated equipment, a stable material system, and strict quality management processes give Chinese car floor mat factories an advantage in product consistency. Even with large-volume orders, they can achieve stable dimensions, consistent fit, and uniform odor, significantly reducing after-sales risks and giving brands and distributors greater peace of mind.

Reason 5: High-quality car floor mats at competitive prices

Chinese-made car floor mats offer a more cost-effective option

(more economical under the same quality standards).

For the same grade of TPE material and the same hot-pressing process, Chinese factories inherently have lower overall manufacturing costs for car floor mats.

For car floor mat distributors, this means they can obtain products at more competitive prices without compromising quality, while maintaining healthier profit margins.

Because of this more reasonable cost structure, Chinese-made car floor mats often maintain a competitive advantage in the end-market, offering "comparable quality at a better price."

Consistent batch quality reduces hidden after-sales costs.

The true value of car floor mats lies not only in price but also in peace of mind.

Stable manufacturing processes and QC procedures ensure consistent size, fit, and odor control, preventing inconsistent quality from batch to batch.

Stable bulk production quality translates to fewer returns, less after-sales communication, and less inventory loss. This allows car floor mat dealers to focus their time and energy on sales rather than handling complaints, which is invaluable.

High development efficiency allows new products to enter the market faster.

With the continuous increase in new car models and electric vehicle platforms, whoever can launch car floor mats compatible with these models faster will be able to capture the market more quickly.

Chinese car floor mat factories have complete model databases, localized molds, and local scanning, resulting in a shorter cycle from development to sample production.

For car floor mat distributors, this translates to"cost-effectiveness in terms of efficiency"—faster new product launches, earlier market returns, and a greater competitive edge.

Flexible and adjustable production capacity suits car floor mat distributors of different sizes.

Chinese car floor mat factories can handle large orders as well as start with reasonable minimum order quantities, making them friendly to distributors at different stages.

Newly established regional car floor mat distributors can start with best-selling models to reduce investment; established brands can place large orders for multiple models and markets at once, and car floor mat factories can quickly match production schedules.

"This capacity flexibility" allows Chinese car floor mat suppliers to better adapt to different market rhythms and is an important part of the cost-effectiveness system.

Conclusion:

In today's increasingly mature global automotive floor mat supply chain, brands choose Chinese manufacturing not because it's cheaper, but because Chinese suppliers possess a more professional, mature, and reliable overall system. From material research and development, vehicle model scanning, and mold capabilities, to production capacity, quality control, and OEM services, Chinese automotive floor mat factories have formed a comprehensive advantage that is difficult to replicate globally.

Among these Chinese manufacturers, Gluebar is one of the leading suppliers of high-quality car floor mats. We specialize in TPE car floor mats, have data covering over 2000 car models, use odorless, environmentally friendly materials with high- and low-temperature resistance, and rely on automated production lines to ensure consistent and stable bulk production of car floor mats.